When designing or troubleshooting a control panel, understanding the difference between NO vs NC momentary push button switches can save you hours of frustration. These tiny components may look the same—but how you wire them determines whether your machine operates smoothly or fails at the worst possible time.

In this guide, we’ll walk through the wiring diagrams, core differences, and common wiring mistakes made by even experienced technicians. You’ll also discover professional recommendations from a leading metal push button switch manufacturer and supplier, covering popular specifications like 16mm / 19mm / 22mm / 25mm / 30mm metal push button switches, 12V / 24V / 110V / 220V illuminated push button switches, and IP65 / IP67 waterproof and stainless steel push button switch options.

Understanding NO vs NC: What Do They Mean?

Before jumping into wiring, let’s define the basics.

- NO (Normally Open): The circuit is open (off) when the button isn’t pressed. Once you press it, the circuit closes—allowing current to flow.

- NC (Normally Closed): The circuit is closed (on) when idle. Pressing the button opens it—cutting off the current.

You can visualize it as “press to start” (NO) and “press to stop” (NC).

| Switch Type | Default State | When Pressed | Common Use |

|---|---|---|---|

| NO (Normally Open) | Circuit open, no flow | Circuit closes, power flows | Start motors, turn on lights |

| NC (Normally Closed) | Circuit closed, current flows | Circuit opens, stops flow | Stop buttons, emergency circuits |

In industrial automation, both are essential. You’ll find NO switches in green “Start” buttons and NC switches in red “Stop” or “Reset” buttons across PLC control panels and machine tool consoles.

Momentary Push Button Switch Basics

A momentary push button switch stays active only while pressed. Once released, it returns to its default NO or NC position.

These metal push button switch come in various configurations and ratings. Industrial engineers often select them based on mechanical durability, voltage, and current load.

| Specification | Example Model | Typical Application |

|---|---|---|

| 16mm / 19mm / 22mm / 25mm / 30mm metal push button switch | Model: YJ19B-B01 | Control panels, test benches |

| 12V / 24V / 110V / 220V illuminated push button switch | Model: YJ22D-R220 | Equipment power indication |

| IP65 / IP67 waterproof stainless steel push button switch | Model: YJ30SS-M18 | Outdoor machinery, marine control |

| Momentary push button switch 10A / 18A | Model: YJ25M-10 | Industrial automation circuits |

When choosing a model, always verify current rating (10A or 18A), material (stainless steel or zinc alloy), and protection grade (IP65 or IP67) depending on the environment.

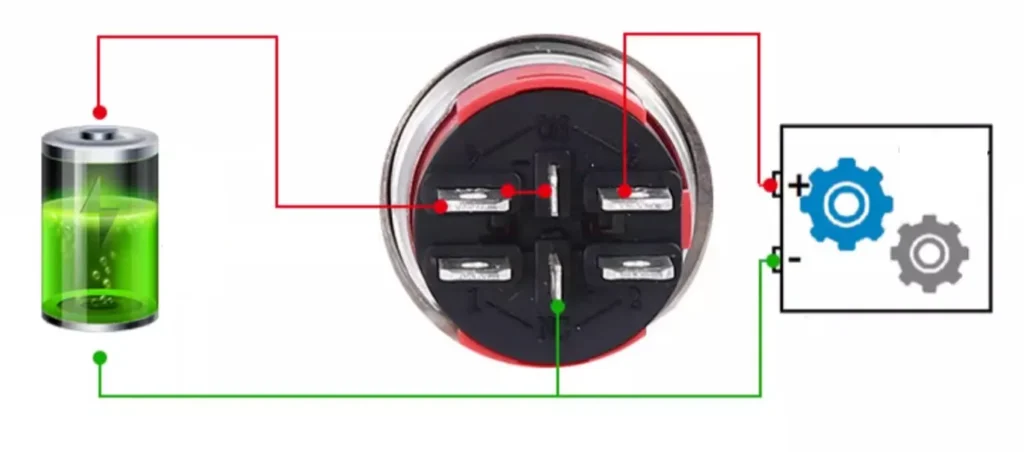

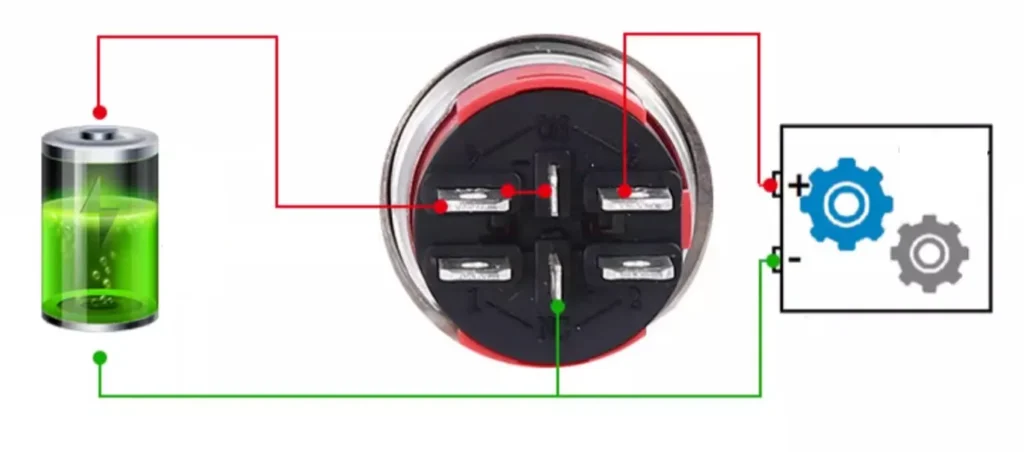

Wiring Diagram: NO vs NC in Action

Let’s imagine you’re wiring a motor start-stop control with a YJ-GQ22B 22mm metal push button switch.

For the NO button:

- Connect one terminal to the live wire (L).

- Connect the other to the relay coil input (usually A1).

- When pressed, the circuit energizes the relay, starting the motor.

For the NC button:

- One terminal connects to the control voltage supply.

- The other connects in series with the relay circuit.

- Pressing it breaks the current flow, stopping the system.

| Circuit Type | Switch Type | Wire Connection | Function |

|---|---|---|---|

| Start Circuit | NO | L → Button → Relay (A1) | Activates relays or loads |

| Stop Circuit | NC | L → Button → Relay (A1) | Interrupts control voltage |

Pro Tip for Engineers: Label every wire and test continuity before powering up. A reversed wire can cause unexpected startup or emergency stop failure.

Common Wiring Mistakes in Control Panels

Even skilled technicians occasionally make avoidable wiring errors. Here’s what to watch out for:

1. Mixing up NO and NC contacts

It’s easy to assume both terminals behave the same. But connecting them incorrectly can reverse the logic of your control system—turning your Start switch into a Stop switch.

2. Using the wrong voltage rating

A 12V push button switch wired into a 220V circuit can overheat or fail instantly. Always match the voltage rating to your power source.

3. Ignoring contact load

Make sure the switch’s rating (e.g., momentary push button 10A / 18A) matches the device load. Underrated switches wear out quickly.

4. Forgetting waterproof sealing

In humid or outdoor applications, always specify an IP65 / IP67 waterproof metal push button switch. Even a drop of liquid can short an unprotected switch.

5. Poor grounding

Failing to connect the LED ground wire of an illuminated push button switch can cause flickering or LED burnout.

Selecting the Right Metal Push Button Switch Manufacturer

In B2B projects, supplier reliability directly affects your product quality. Partnering with a professional metal push button switch manufacturer or supplier ensures stable supply, OEM customization, and reliable testing reports (e.g., UL, CE, or RoHS certifications).

When choosing a manufacturer, check these factors:

- Product range covering 16mm to 30mm push button sizes.

- Multi-voltage options (12V / 24V / 110V / 220V).

- Sample support for prototyping and panel testing.

- Stainless steel materials with IP65/IP67 ratings for durability.

For OEM projects, always request datasheets and wiring samples to integrate efficiently into your automation control panels, vending systems, or marine control boxes.

Need a reliable supplier? Get in touch with our team for quick quotations and free samples—we help engineers and procurement teams find the right switch for every project.

Applications Across Industries

From robotic systems to marine control panels, the NO vs NC momentary push button switch is a small but critical component in modern automation.

Common uses include:

- CNC machines and PLC start-stop stations

- Industrial coffee machines and vending systems

- Automotive dashboards and control interfaces

- Elevator panels, access control, and testing benches

| Industry | Recommended Switch Type | Key Feature |

|---|---|---|

| Industrial Automation | 22mm stainless steel momentary push button | 18A rating for heavy loads |

| Marine Equipment | 25mm IP67 waterproof illuminated push button | Corrosion resistance |

| Automotive Controls | 16mm 12V metal push button | Compact and reliable actuation |

| Smart Home and IoT Devices | 19mm 24V illuminated switch | Visual feedback and long life |

Each application demands a balance of electrical durability, mechanical life, and environmental protection.

Maintenance and Lifespan Tips

Proper maintenance extends lifespan and ensures safe operation:

- Clean contact terminals every few months.

- Tighten connectors to prevent vibration loosening.

- Avoid operating under the rated load for extended periods.

- For illuminated models, use the correct resistor for LED supply voltage.

With these practices, your push button switches can easily surpass 1,000,000 cycles of reliable performance.

Understanding the NO vs NC YJ-GQ16/19/22 Colorable metal button momentary push button switch wiring diagram is essential for engineers and technicians working in industrial control. Connecting the correct contact type not only ensures safety but also saves cost from accidental miswiring.

When sourcing components, make sure you work with a trusted metal push button switch manufacturer or supplier offering customizable options like 16mm to 30mm metal push button switches, 12V / 24V / 110V / 220V illuminated types, and IP65/IP67 stainless steel models.

For B2B buyers, choosing a reliable partner means stable quality, technical support, and timely deliveries—a crucial part of any successful automation project.

Need help selecting your next switch model? Contact our sales team today to request a sample or project quotation—we’ll help you find the perfect fit.

FAQ

Only if your control logic allows it. Replacing one type with another can reverse functions—always check wiring diagrams first.

It means the button only stays active while pressed—unlike a latching switch that stays engaged.

Yes, choose 220V illuminated push button switches designed for industrial mains voltage.

Always use IP65/IP67 waterproof stainless steel push button switches to prevent moisture ingress.

Most control panels use 22mm or 25mm metal push button switches, depending on the enclosure design and space constraints.

Need high-quality NO vs NC momentary push button switch wiring? Contact us now for reliable products and personalized support!