FOOD INDUSTRY

Food processing equipment often needs to be cleaned, and its control switches must have a high waterproof rating. Moreover, in order to achieve a dust-free and sterile production environment, the risks brought by production equipment need to be strictly controlled. We aim to provide better solutions.

Application Overview

The AC contactors, relays, button switches, signal lights and other products produced by Yijia Industrial Control Electrical Appliance Co., Ltd. have the following applications in the food industry:

Production equipment control

-Motor control: AC contactors are used to control the motors of food processing equipment, such as mixers, grinders, filling equipment, conveyor belts, packaging machines, etc., to achieve the start, stop, and forward/reverse rotation of the equipment, ensuring the smooth progress of the production process.

-Logic control: Relays can achieve logical control of multiple motors or other actuating components in food production equipment, completing complex action processes according to preset programs and conditions, such as controlling the start and stop of equipment at different workstations in an automated production line.

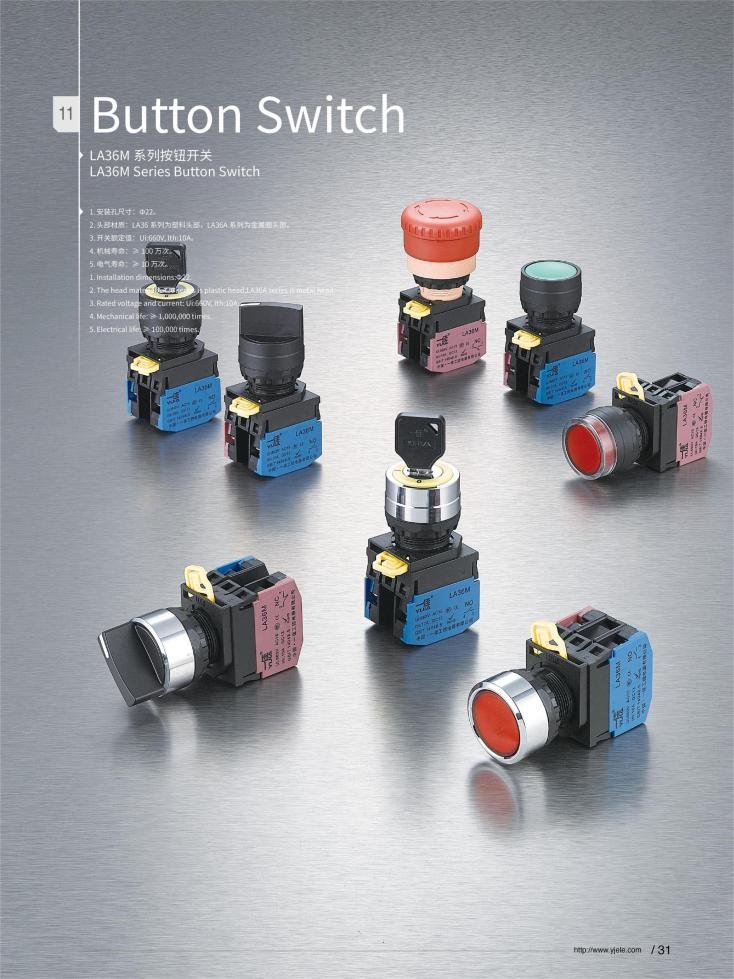

-Equipment operation: Button switches are used to operate the start stop, emergency stop, reset and other functions of food processing equipment, making it convenient for workers to operate according to production needs. The illuminated button switch can also indicate the operating status of the device through the light, such as red indicating that the device is stopped and green indicating that the device is running.

Environmental Control and Monitoring

-Temperature and humidity control: Relays can control the air conditioning system, dehumidifiers, humidifiers, and other equipment in the food workshop. Based on the environmental parameters detected by temperature and humidity sensors, the corresponding equipment can be automatically started or stopped to maintain stable temperature and humidity in the workshop. Button switches and signal lights can be used to control and indicate the operating status of these environmental control devices.

-Ventilation and lighting control: Control the start and stop of the ventilation system’s fans through relays, maintain air circulation in the workshop, and eliminate odors and moisture. At the same time, relays can also be used to control the switching of lighting systems, achieving automated control of lighting. Button switches are used to manually control the on and off of ventilation and lighting equipment, and signal lights can display their working status.

Security and alarm system

-Safety protection: Install travel switches as safety protection devices in some hazardous areas of the food production workshop, such as near high-speed equipment, high-temperature areas, etc. When personnel or objects approach the dangerous area, the travel switch is triggered, and the relevant equipment is controlled to stop running through a relay to ensure the safety of personnel and equipment.

-Fault alarm: When the food processing equipment malfunctions, the sensor detects the fault signal and triggers the alarm device through a relay, such as an audible and visual alarm. The signal light flashes and the buzzer sounds to remind the staff to handle the fault in a timely manner. The button switch can be used to manually test whether the alarm system is working properly and reset the alarm after troubleshooting.