When you choose a momentary push button switch 10A / 18A for your control panel, you are really deciding how your whole machine behaves under real-world stress. One underrated hero in this category is the YJ-GQ22A/25A high current metal push button switch, designed exactly for demanding industrial buyers who cannot afford nuisance trips or melted contacts. In this article, I will walk you through what makes a 10A / 18A momentary push button switch different, where the YJ-GQ22A/25A shines, and how you can spec, compare, and purchase it like a pro.

And yes, I promise not to bore you like a 200‑page datasheet. If you like what you see, you can always send an inquiry with your BOM and quantity at the end.

What is a momentary push button switch 10A / 18A?

A momentary push button switch is a device that only changes the circuit state while you keep it pressed; once your finger leaves, a spring returns it to its original position. In industrial control, this is the classic “Start”, “Jog”, or “Reset” behavior where you want temporary action, not a latched on/off state.

When we talk about a momentary push button switch 10A / 18A, we are referring to the current rating that the contacts can safely carry under specified conditions. Many small control buttons are only rated 3A or 5A, but high current momentary push buttons like the YJ-GQ22A/25A are engineered to handle up to 18A at 250V for AC-15 duty, which is a serious upgrade for heavy loads and motor circuits.

Typical electrical ratings (reference class)

So, when someone in your team simply says “just use a momentary push button,” you might want to reply: “Sure, but is it 3A toy level or 18A panel boss?”

Inside the YJ-GQ22A/25A high current series

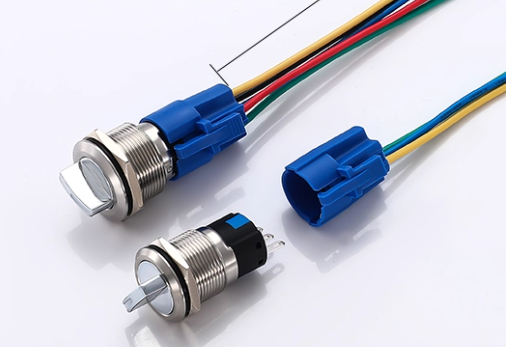

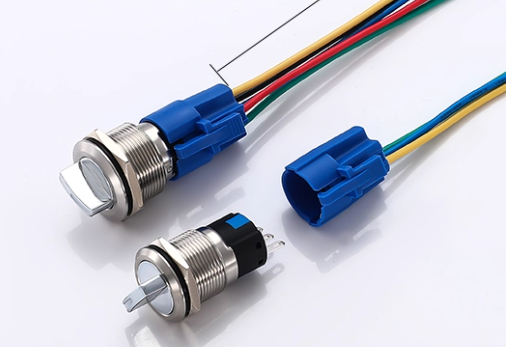

Now let’s talk specifically about the YJ-GQ22A/25A metal push button switch, the main character of this story. This series is designed as a high current metal button range, with Φ22 mm (GQ22A) and Φ25 mm (GQ25A) mounting sizes, aimed at applications that need robust 10A / 18A switching capacity in a compact footprint.

The switch uses a metal head (flat or high), metal shell (stainless steel or chrome‑plated brass), PBT base, and silver alloy contacts, combining mechanical strength with reliable conductivity. Operation can be momentary or maintained, but in this article we focus on the momentary push button switch 10A / 18A configuration commonly used in start and jog circuits.

Core technical data for YJ-GQ22A series (example)

The GQ25A variant carries the same design philosophy but with a 25 mm cut-out, giving you more panel presence and often slightly more robust mechanical feel, which some operators love in heavy machinery. If you are retrofitting older plastic buttons on big machines, the YJ-GQ22A/25A family is an easy drop‑in upgrade path with a more premium look and higher current rating.

Why choose a 10A / 18A momentary push button for industrial panels?

You might ask: “Do I really need such a high current rating? My PLC input only draws milliamps!” Fair question—and a very common misunderstanding in B2B purchasing.

In real industrial environments, a momentary push button switch is often used not only for signal level but also for direct control of contactor coils, motor starters, or even resistive loads, depending on the design tradition in your market. A 10A or 18A rating gives you extra thermal margin, better endurance for inrush currents, and less risk of contact welding under abnormal conditions.

Benefit comparison: low current vs high current buttons

So if your product goes into harsh applications—CNC machines, industrial elevators, chargers, commercial kitchen equipment, or automation panels—moving up to a momentary push button switch 10A / 18A is usually a smart, low‑cost insurance policy. And your service team will secretly thank you for fewer burnt buttons over time.

YJ-GQ22A vs YJ-GQ25A: which one suits your project?

Since the product keyword is YJ-GQ22A/25A, let’s look at how to choose between the 22 mm and 25 mm versions when you design or upgrade a panel. Both are high current metal push button switches, both support momentary operation, and both are suitable for 10A / 18A use depending on specification.

The real differences are more practical: panel cut-out standard, ergonomics, and visual impact. In some markets 22 mm cut-outs are dominant (especially in modern modular control systems), while 25 mm buttons are more common in older, heavy-duty equipment or where gloved operation is frequent.

Quick comparison of YJ-GQ22A and YJ-GQ25A families

If your client sends you a drawing with “22 mm hole” clearly marked, then YJ-GQ22A is the natural choice. When you see larger 25 mm positions, or when the operator will wear thick gloves (such as in food processing or outdoor power equipment), YJ-GQ25A often offers better ergonomics.

By the way, if you already have your panel layout and BOM ready, you can send the design with your target current rating, voltage, and quantity to the supplier—you will get a much faster and more accurate quotation.

Key specifications B2B buyers should check

Procurement teams and engineers do not just buy a “nice shiny metal button.” You buy a risk profile, warranty assumptions, and brand reputation. Let me highlight several technical points you should always check when sourcing a momentary push button switch 10A / 18A such as YJ-GQ22A/25A.

- Rated current and utilization category

Look for AC-15 or DC-13 data, not just a random “18A” headline. The data in the GQ22A class clearly lists different currents for resistive vs inductive loads at various voltages, which is what you want for serious engineering decisions. - Contact configuration (NO/NC)

Options usually include 1NO, 1NC, 1NO1NC, 2NO, etc. This affects how many circuits you can control and whether you can integrate safety interlocks without extra relays. - Mechanical and electrical life

For high current metal push buttons, mechanical life around 1 million operations and electrical life of 0.1–0.2 million operations is typical. For applications like repeated jogging, you may want to keep an extra safety margin here. - IP rating and environment

Many metal buttons (including IN‑class 22 mm high current ranges) offer IP65 or IP67 on the panel side, which is crucial in outdoor, washdown, or dusty environments. When you see IP65 in the spec sheet for a high current model, that’s usually enough for general industrial environment if the panel is properly sealed. - Material and appearance

Stainless steel or chrome-plated brass housings are common for anti‑vandal and high current metal push button switches. Stainless steel gives excellent corrosion resistance; plated brass often offers a smoother finish and slightly lower cost.

Spec checklist for RFQ

If you send an inquiry including this basic checklist, your supplier will probably reply faster—and happily—because you sound like you know what you are doing.

Typical applications for YJ-GQ22A/25A in B2B projects

Where do high current momentary push button switch 10A / 18A models actually get used? Pretty much anywhere a rugged operator interface is needed with medium to high current.

Common application areas include:

- Industrial machine start/stop stations and jog functions.

- Motor control panels, especially for pumps, fans, and compressors.

- Elevators and lifting equipment control boxes.

- Charging piles and new energy equipment operator panels.

- Food processing and kitchen machinery, where metal buttons are easier to clean.

- Power distribution and generator control panels.

Application–requirement mapping

If your project falls into any of these categories and your current specification still lists a 3A plastic button, it might be time to upgrade to something in the YJ-GQ22A/25A class.

How to select the right YJ-GQ22A/25A configuration

Choosing a specific configuration within the YJ-GQ22A/25A range is basically a small puzzle with a few pieces: mounting size, operation type, contacts, and environment.

First, confirm your panel cut-out: 22 mm or 25 mm. Second, confirm you want a momentary push button, not maintained; momentary is safer and more intuitive for start and jog functions. Third, define your contacts (for example, 1NO1NC for holding circuit plus indicator feedback).

Example selection matrix

If you are not sure which exact combination to choose, you can send your load data (voltage, current, AC or DC, and application) in your RFQ—an experienced manufacturer can then match the right high current metal push button model for you.

When you look beyond the shiny metal surface, a model like YJ-GQ22A/25A is basically a compact insurance policy for your panel: high current rating, robust contacts, and proven life in industrial conditions. If you are working on a new project or upgrading an old machine and need a reliable momentary push button switch 10A / 18A, feel free to prepare your BOM (panel size, contact type, voltage, quantity) and send an inquiry—you will get a more targeted recommendation and a clearer total cost of ownership.

FAQ

Not necessarily. While you can use lower-rated buttons for PLC inputs, a high current momentary push button switch 10A / 18A gives you more flexibility to reuse the same part across different projects and provides extra safety margin against unexpected overloads.

Yes, as long as the specific model offers IP65 or higher protection on the panel side and the enclosure is properly sealed, it can be used in many outdoor or damp applications such as EV charging, food processing, or industrial washing equipment.

Momentary versions return to their original position when released and are typically used for start, reset, or jog; maintained versions stay in their new state, acting more like an on-off switch for simple circuits. Since this article focuses on momentary push button switch 10A / 18A, you would normally choose the momentary codes in the YJ-GQ22A/25A series.

In many 22 mm high current lines, mechanical life is specified up to 1,000,000 operations and electrical life around 100,000–200,000 operations depending on load type and wiring. In normal industrial use, that typically translates to many years of service, especially when switching contactors instead of direct motor loads.

You should at least include panel hole size (22 mm or 25 mm), operation type (momentary), contact configuration (for example, 1NO1NC), rated voltage and current of your load, expected annual quantity, and any special requirements such as stainless steel housing or specific IP rating. With this info, your supplier can quickly recommend a suitable momentary push button switch 10A / 18A model and provide accurate pricing.