YIJIA metal push button switch are designed for industrial applications, combining high reliability, durability, and consistent delivery. OEM customization is supported, covering multiple sizes and specifications. They operate stably under harsh conditions such as vibration, humidity, and high-frequency operation, making them ideal for mechanical equipment and automated control systems.

With years of manufacturing experience, YIJIA delivers stable quality metal push button switches backed by strict quality control and reliable lead times. We support OEM/ODM projects and ensure every order meets industrial standards.

We provide stable and continuous supply of metal push button switch models to support fast shipment and short lead times. With strong production capacity and efficient logistics, we ensure reliable delivery for your ongoing projects.

A Metal Push Button Switch is an electrical control device made of durable metal materials, used to open or close circuits in machinery, automation systems, or industrial control panels.

Our switches are typically made of stainless steel or aluminum alloy, ensuring high strength, corrosion resistance, and long service life even in harsh industrial environments.

Yes. Most models are rated IP65 or IP67, offering excellent protection against water, dust, and oil for both indoor and outdoor use.

Absolutely. We offer customization for size, voltage, LED color, symbols, and terminals to meet your specific application needs. OEM and ODM orders are welcome.

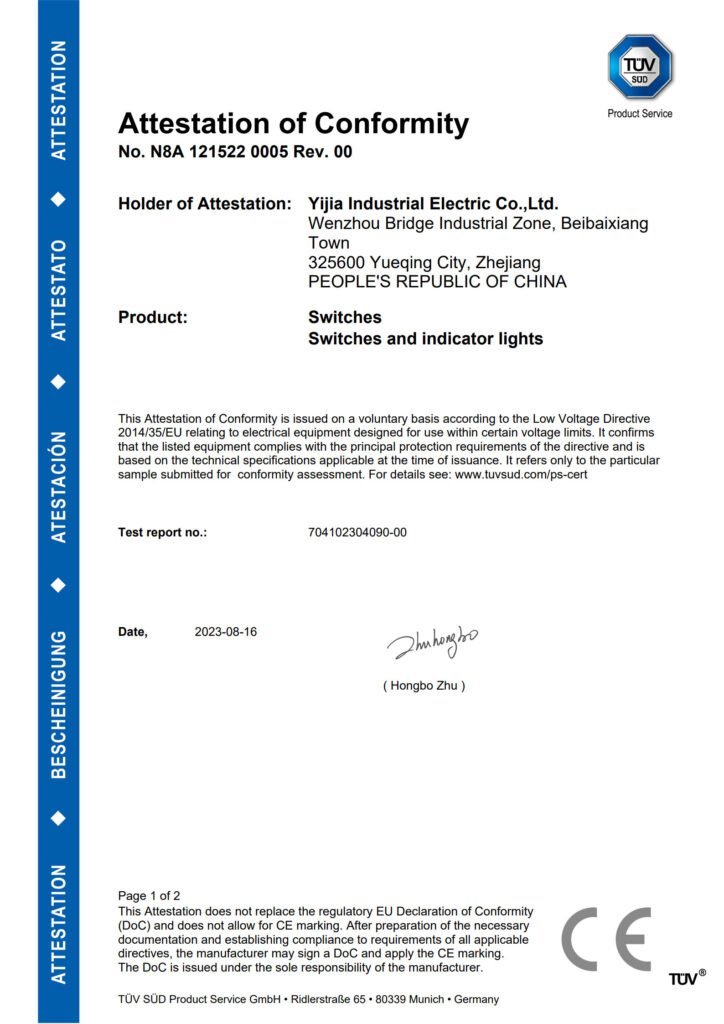

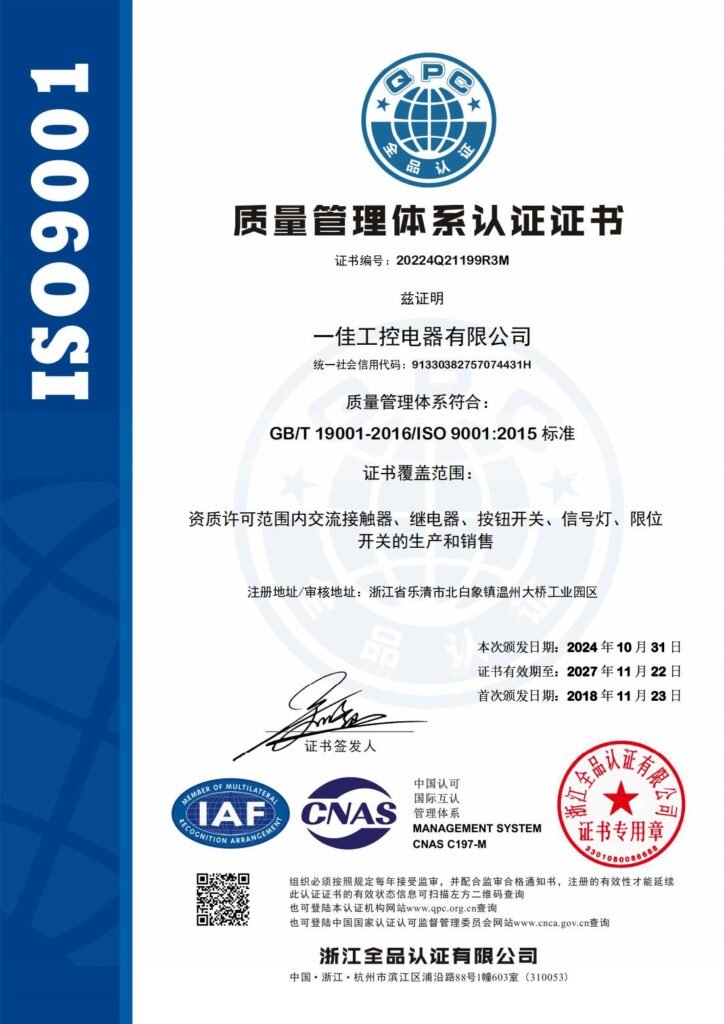

Our products comply with CE, RoHS, and ISO9001 standards to ensure safety, reliability, and quality in every switch we produce.

They are widely used in industrial machinery, control panels, marine equipment, automotive electronics, and automation systems.

You can contact our sales team directly through the inquiry form or email. We respond quickly with detailed specifications, pricing, and shipping options for global customers.

Yes. Our technical team offers professional after-sales support, installation guidance, and long-term service to ensure smooth operation of your equipment.

We will respond to your inquiry within 24 hours

We value your privacy

We use cookies to enhance your browsing experience, serve personalised ads or content, and analyse our traffic. By clicking "Accept All", you consent to our use of cookies.