Ever wondered what keeps your metal push button switch working flawlessly even in harsh or wet conditions? The secret lies in its IP rating — a standard that defines how well a switch resists water and dust intrusion. For industrial control panels, outdoor equipment, medical devices, or automotive applications, understanding these IP ratings is essential to ensure reliability and durability.

In this article, we’ll dive deep into the waterproof and dustproof capabilities of metal push button switches, focusing on IP65, IP67, and IP68 ratings. You’ll also learn about the materials and sealing techniques that help achieve these protective standards. Whether you’re an engineer, purchasing manager, or simply curious, this guide will clarify your choices and help you pick the right switch for your needs.

Ready to upgrade your switches or need custom solutions? Feel free to contact us anytime for expert advice or a personalized quote on high-quality metal push button switches tailored to your waterproofing requirements.

What Is IP Protection Rating?

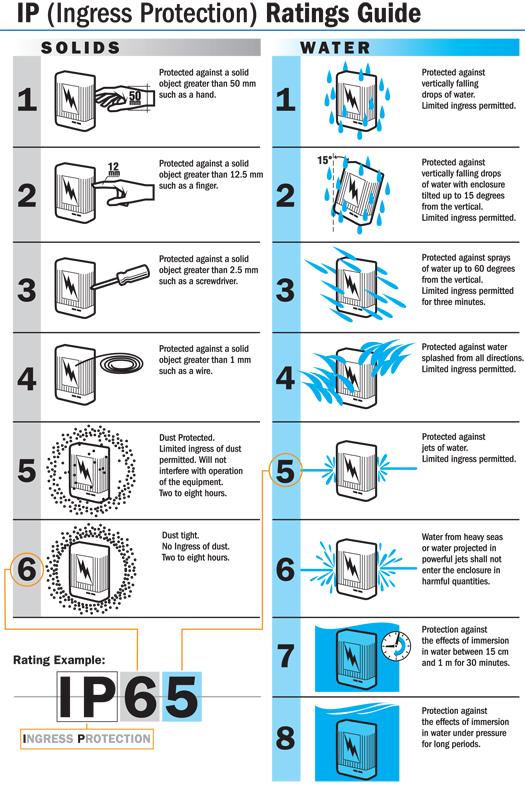

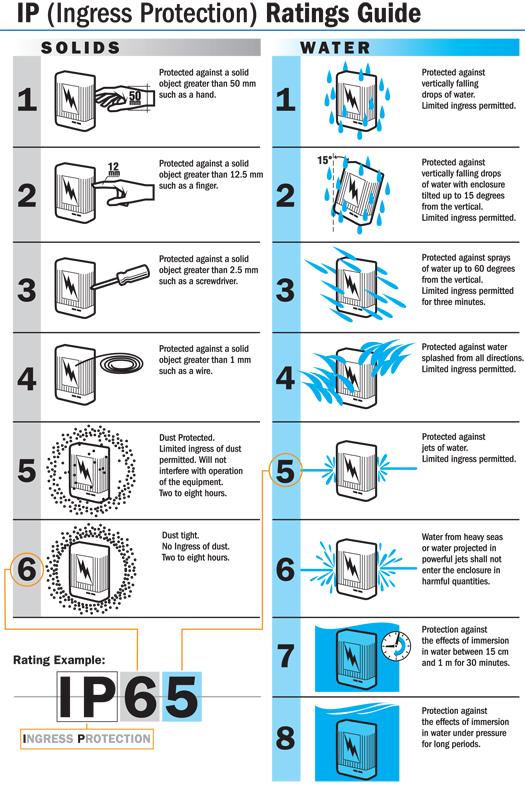

The “IP” in IP rating stands for Ingress Protection and is an international standard (IEC 60529) that classifies the degree of protection an electrical enclosure provides against intrusion from solids and liquids.

How to Read IP Ratings

An IP rating looks like IPXY, where:

| Position | What it Means | Range | Description |

|---|---|---|---|

| X | Protection Level Against Solid Particles | 0-6 | 0 means no protection; 6 means dust-tight |

| Y | Protection Level Against Liquids | 0-9 | 0 means no protection; 9 means protection against high-pressure washdowns |

For example, IP65 means dust-tight (6) and protected against water jets (5). IP67 suggests dust-tight and protection against temporary immersion. IP68 means dust-tight and protection against continuous immersion under conditions specified by the manufacturer.

IP65, IP67, IP68 What’s the Difference for Metal Push Button Switches?

These three IP ratings are the most common for metal push button switches, especially in industrial and outdoor environments. Let’s break down their differences:

| IP Rating | Dust Protection | Water Protection | Typical Applications |

|---|---|---|---|

| IP65 | Complete dust-tight | Water jets from any direction | Outdoor controls, moderately wet areas |

| IP67 | Complete dust-tight | Temporary immersion (up to 1m for 30 min) | Emergency stops, automotive, outdoor devices |

| IP68 | Complete dust-tight | Continuous immersion (greater depth/time varies) | Underwater equipment, harsh marine/agriculture settings |

Why does this matter? Because using a switch with an inadequate IP rating can lead to failure due to moisture or dust ingress, affecting safety and performance.

How Metal Push Button Switches Achieve Waterproof and Dustproof Protection

Sealing Principles and Technologies

Achieving a high IP rating requires good sealing. Designers use various materials and methods for effective protection:

- Silicone or Rubber O-rings: These flexible rings create tight seals around the button shaft.

- High-precision machining: Ensures components fit perfectly without gaps.

- Multi-layer sealing: Combines gaskets, sealants, and mechanical barriers.

- Enclosed switch housing: Prevents dust and liquid entry.

- Special coatings: On metal surfaces to enhance corrosion resistance.

By carefully combining these elements, manufacturers can ensure that switches meet or exceed their claimed IP rating, such as IP67 or IP68.

The discount is extremely generous!

Need a customized metal push button switch that fits perfectly? Contact Yijia now for expert solutions and unbeatable quality!

What Sealing Materials and Processes Enable IP68 Metal Push Button Switches?

Reaching the IP68 rating means your metal push button switch can survive continuous immersion in water. This requires:

Materials Used

| Material | Purpose | Benefits |

|---|---|---|

| Silicone Rubber | Primary sealing gasket material | High flexibility and temperature tolerance |

| Fluoroelastomer (FKM) | Chemical-resistant O-rings | Resistant to oils, fuels, and chemicals |

| Polybutylene Terephthalate (PBT) or PA66 Plastic | Housing and insulation | Strong, durable, and good dimensional stability |

| Stainless Steel | Button face and housing | Corrosion resistance and strength |

Manufacturing Processes

- Ultra-precision molding to create watertight seals and smooth surfaces.

- Ultrasonic welding to fuse plastic parts without gaps.

- Pressure testing to verify sealing under simulated real-world conditions.

- Multi-step assembly inspections to ensure consistency.

Common Metal Push Button Switch IP Ratings and Their Applications

| IP Rating | Description | Example Use Case | Industry Examples |

|---|---|---|---|

| IP65 | Dust tight, water jets protected | Outdoor control panels | Public kiosks, lighting controls |

| IP67 | Dust tight, temporary immersion | Vehicle dashboard controls | Automotive, industrial machinery |

| IP68 | Dust tight, continuous immersion | Underwater controls, marine equipment | Marine, agriculture, medical devices |

How to Choose the Right Metal Push Button Switch for Your Needs?

When selecting a metal push button switch, consider these factors:

- Environment — Will the switch be exposed to dust, rain, or submerged in water?

- Electrical ratings — Voltage and current must match your circuit.

- Mounting type — Panel mount or surface mount affects installation ease.

- Material and durability — Stainless steel or plastic based on corrosiveness.

- IP rating required according to the exposure risk.

Pro tip: Don’t overpay for higher IP protections than necessary, but never under-protect!

If uncertain, contact us for a custom recommendation that balances cost and protection perfectly.

Choosing the right Metal Push Button Switch with an appropriate IP rating is vital to success in harsh or demanding environments. Whether it’s the robust protection of IP65 or the ultimate waterproofing of IP68, understanding these standards helps you pick a switch that lasts and performs reliably.

Don’t leave your equipment vulnerable — invest in quality switches designed with advanced sealing materials and craftsmanship. Reach out to us today to find the perfect waterproof metal push button switch for your project. With the right choice, your systems will stay safe and efficient for years to come!

FAQ

The testing involves exposing the switch to standardized dust environments and water sprays or immersions, then checking for ingress. This verifies the switch meets claimed IP protection.

Generally, yes. Better sealing materials and processes improve durability, but also can make switches slightly harder to press due to tighter seals.

Yes, but only under conditions specified by the manufacturer, such as maximum depth and duration.

Keep seals clean, avoid excessive force, and inspect regularly for wear or damage.