A miniature limit switch is a small electrical switch typically used to detect the position or end of mechanical movement. It uses mechanical contact or non-contact mode to trigger the switch action when it detects that the object reaches the preset position, thereby controlling the operating status of the equipment. Due to their small size, sensitive operation and high reliability, micro limit switches are widely used in household appliances, automation equipment, industrial control systems and other fields.

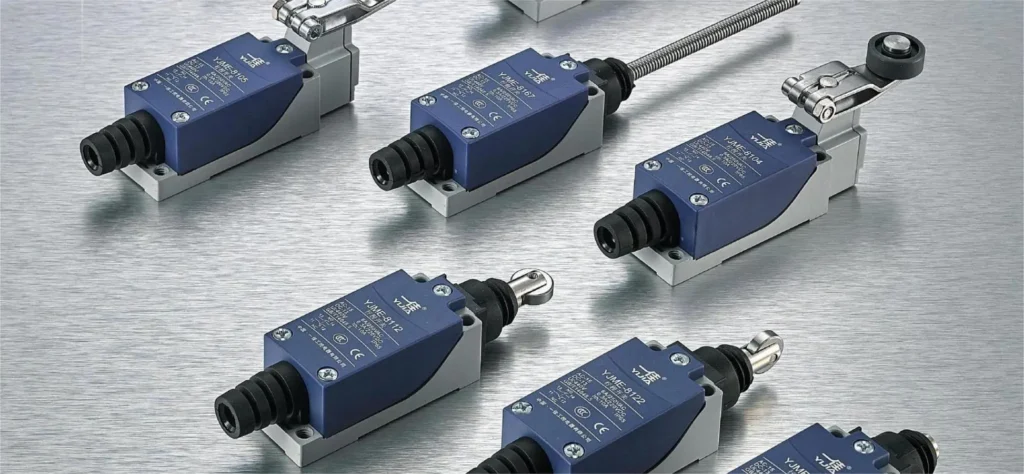

Micro limit switches can be divided into the following common types according to their structure and functions:

1. Roller type micro limit switch

The main feature of the roller type micro limit switch is that it has a small roller. When a mechanically moving object contacts the roller and pushes it, the roller will rotate, thereby triggering the switch. Roller type switches are often used where linear or rotary motion needs to be detected, such as robotic arms and conveyor belts on automated production lines. The switch features low friction and high sensitivity, allowing it to respond accurately to light contact.

2. Button type micro limit switch

Push-button type micro limit switches trigger the internal switching element by directly pressing the button. It has a simple structure and is easy to install. It is usually used in application scenarios that require direct contact, such as buttons of household appliances and automatic door control devices. The push-button switch has a small triggering force and is easy to operate, making it suitable for various simple mechanical or electronic equipment.

3. Lever type micro limit switch

Lever-type micro limit switches have a lever that triggers the switch when pushed by a mechanically moving object. Lever-type switches are suitable for situations that require a large range of motion and flexible triggering, such as industrial equipment, automation devices, etc. The levers can be designed in different lengths and shapes according to requirements to adapt to various application environments. Its advantages are flexible movement, adjustable trigger points, and strong adaptability.

4. Blade type micro limit switch

Blade-type micro limit switches have a thin blade that triggers the switch when bent by mechanical force. This kind of switch is often used to detect slight movements or small displacements, and is suitable for applications with high sensitivity requirements, such as micro mechanical devices, electronic instruments, etc. The blade type switch has the characteristics of high sensitivity and low triggering force, and can detect very subtle displacement changes.

5. Rotary micro limit switch

Rotary micro limit switches trigger internal switching components through rotational movement and are often used for limit detection of rotating machinery or devices. For example, in some automated mechanical equipment, when the rotating part reaches a certain position, a switch is triggered to control the stop or reversal of the equipment. Rotary switches have high precision and reliability and are suitable for applications requiring precise position control.

6. Micro-action micro limit switch

The inching micro limit switch is a highly sensitive small switch that is usually used in applications that require high precision and fast response, such as precision instruments, electronic equipment, computer mice, etc. Micro switches are characterized by very small triggering force, fast response speed, and the ability to respond in a very short time. Its internal structure is precise and can withstand repeated operations while maintaining reliability.

The working principle of the micro limit switch is based on mechanical triggering and electrical signal conversion. The circuit inside the switch is triggered by mechanical movement, thereby opening or closing the circuit. The specific working principle is as follows:

working principle

- Mechanical triggering: When external mechanical moving parts (such as push rods, rollers, levers, etc.) reach the preset position, they will contact the triggering part of the micro limit switch. Depending on the type of switch, the triggering component may be a button, wheel, blade, or lever.

- Contact action: After the trigger component is acted upon by an external force, it pushes the internal spring or other mechanical components, causing the contacts inside the switch to move. Movement of the contacts changes the state of the switching circuit, converting the circuit from a closed state to an open state, or from an open state to a closed state.

- Electrical signal output: After the contact moves, the circuit status of the micro limit switch changes and the corresponding electrical signal is output. These electrical signals can be used to control other electrical equipment or systems, such as stopping motors, starting alarms, switching control loops, etc.

Example description

Taking the roller type micro limit switch as an example, when the detected object moves to a specific position, the object will contact and push the roller. The rotation of the roller drives the internal mechanical structure to move, causing the internal contacts to move and change the circuit state. At this time, the switch outputs an electrical signal indicating that the object has reached the preset position.

Contact type

There are many types of contacts for micro limit switches, common ones include:

- Normally open contact (NO): The circuit is open under normal conditions and closed when triggered.

- Normally closed contact (NC): The circuit is closed under normal conditions and opened when triggered.

- Change-over contact (COM): Normally used in conjunction with normally open and normally closed contacts to switch between the two.

Micro limit switches are widely used in various scenarios requiring position detection and control due to their compactness, sensitivity and reliability. Here are some common application scenarios:

1. Industrial automation

In automated production lines, micro limit switches are used to detect the position and motion status of mechanical components. For example:

- Robotic arm: Detect the end position of the robotic arm to ensure precise positioning and safe operation.

- Conveyor belt: Monitor the position of objects on the conveyor belt and control the start and stop of the conveyor belt.

- Processing equipment: In CNC machine tools, punch presses and other equipment, limit switches are used to detect the position of the tool or workpiece to prevent overtravel damage.

2. Household appliances

Micro limit switches play an important role in various household appliances to ensure the normal operation and safety of the equipment. For example:

- Washing machine: Detect the opening and closing status of the washing machine door to ensure that the program can only be started when the door is closed.

- Microwave oven: Make sure the microwave door is closed to prevent it from starting when the door is not fully closed.

- Refrigerator: Detect the status of the refrigerator door, control the light switch and adjust the temperature of the refrigerator compartment.

3. Security equipment

In security equipment, miniature limit switches are used to monitor and control the status of safety devices. For example:

- Elevator: Detect the opening and closing status of the elevator door to ensure that the elevator can start running only after the door is closed.

- Automatic door: Monitor the opening and closing of the automatic door to prevent misoperation when the door is not fully closed.

- Anti-theft alarm system: Install limit switches on anti-theft doors and windows to trigger an alarm when the doors and windows are opened.

4. Medical equipment

- In medical equipment, miniature limit switches are used for precise control and detection. For example:

- Operating table: Detect the height and angle of the operating table to ensure precise positioning during surgery.

- Laboratory equipment: In centrifuges, thermostats and other equipment, monitor the opening and closing status of the lid to ensure safe operation.

5. Automobile industry

Micro limit switches are also widely used in automobiles to detect and control the status of various automobile components. For example:

- Car door: Detect the opening and closing status of the car door, and control the interior lighting and alarm system.

- Seat position: Detect the adjustment position of the seat to ensure the comfort and safety of the driver and passengers.

- Trunk: Monitor the opening and closing status of the trunk lid to prevent the trunk from being accidentally opened while driving.

6. Office equipment

In office equipment such as printers and copiers, miniature limit switches are used to detect the status of paper and covers. For example:

- Printer: Detect the paper feeding and output status to ensure the smooth printing process.

- Copier: Monitor the opening and closing of the cover to ensure the normal progress of the copying process.

7. Electronic equipment

In some precision electronic equipment, miniature limit switches are used to detect and control the status of internal components. For example:

- Computer mouse: The internal micro switch is used to detect the pressed and released state of the keys and provide user input.

- Keyboard: In mechanical keyboards, micro switches are used to detect the movement of each key to improve input accuracy and response speed.