In-depth analysis of panel door limit switches

What is a panel door limit switch

Panel door limit switch is a controller installed on mechanical or electrical equipment to detect whether the position of mechanical components (such as doors, covers, etc.) reaches a preset limit point. When the mechanical component reaches or leaves this preset position, the limit switch will be triggered to control the on and off of the circuit to ensure the safety and accuracy of equipment operation. This kind of switch is usually used to control the extreme position of mechanical movement to prevent the equipment from exceeding the safe operating range. Panel door limit switches are widely used in various industrial automation and mechanical devices, especially where precise control of the position of mechanical components is required.

The function of the panel door limit switch

The main function of the panel door limit switch is to ensure that the mechanical equipment works within a safe and predetermined operating range. It controls the start, stop, or other functions of equipment by monitoring the position of equipment components, such as panel doors. Specific functions include:

- Safety protection: Limit switches can prevent mechanical equipment from exceeding its maximum or minimum safe operating range and avoid equipment damage or operator injury. For example, installing a limit switch on an elevator door or industrial machine door can allow the machine to operate until the door is fully closed.

- Position control: In automated production lines, panel door limit switches are used to precisely control the position of mechanical components to ensure the accuracy and repeatability of the production process. For example, on an assembly line, limit switches ensure that a robotic arm or workpiece reaches the correct position before proceeding to the next step.

- Signal transmission: When the panel door reaches a specific position, the limit switch will send a signal to the control system to notify the current status of the system components and help the system make corresponding adjustments or decisions.

- Energy Saving and Consumption Reduction: Limit switches help save energy and reduce operating costs by controlling equipment to operate only when needed.

Working principle of panel door limit switch

The working principle of the panel door limit switch is based on the physical movement of mechanical contacts to control the opening and closing of the circuit. This switch is simple in design but extremely effective. Here’s how it basically works:

- Physical triggering: Panel door limit switches typically consist of a movable arm or rod (stick) and a built-in electrical contact point. When a panel door or other mechanical part moves to a specific position, it pushes or pulls on this lever.

- Contact point action: Movement of the contact rod causes internal contact points to close or open. These contacts are part of a circuit, and their closing or opening controls the flow of electricity through the circuit, thereby controlling the device’s power switch or other electrical function.

- Signal output: When the contacts are closed, current can pass through, sending an “on” or “continue operation” electrical signal to the device’s control system. Conversely, when the contacts open, the current is cut off, sending a “off” or “stop operation” signal.

- Reset mechanism: In some types of limit switches, once the contact rod is released, it will automatically return to its original position through a built-in spring or other mechanism, ready for the next trigger.

The design of the panel door limit switch can be a simple mechanical type, or it can integrate more complex electronic sensing components, such as magnetic or photoelectric sensors, to adapt to different application needs and environments. The reliability and precision of this switch make it an indispensable component in industrial automation.

How to choose a suitable panel door limit switch

When purchasing the right panel door limit switch, there are several factors to consider to ensure that the switch you choose meets the needs of your specific application. Here are some key selection criteria:

- Operating environment: Consider the environmental conditions in which the switch will be used, including temperature, humidity, dust, and possible corrosive substances. Different environmental conditions may require limit switches of different materials and protection levels, such as waterproof, dustproof or high temperature resistance.

- Electrical parameters: Review the voltage and current specifications of the switch to make sure they match the electrical requirements of the application system. Additionally, consider the switch’s contact type (normally open or normally closed) and whether features such as dual breakpoints are required.

- Mechanical characteristics: Consider the required contact force and travel distance. Different applications may require different trigger sensitivities and reset characteristics.

- Installation method: Choose the appropriate installation configuration according to the actual installation conditions on site, such as right-angle installation, flat installation, etc. Make sure the selected switch is mounted in a manner that accommodates the mechanical design.

- Durability and Reliability: When choosing a brand and model, give priority to products known to have high durability and reliability. You can evaluate this by looking at product reviews, consulting industry experts, or referring to the experience of your peers.

- Certifications and standards: Ensure that the limit switch you purchase complies with international or domestic safety standards and certifications, such as CE marking, UL certification, etc., which helps ensure the safety and compliance of the product.

- Supplier support: Choose a supplier with good after-sales service and technical support so that you can get quick help if you encounter problems during use.

Application scenarios

Panel door limit switches play an important role in a variety of industrial and commercial applications. Here are some common application scenarios:

- Mechanical equipment safety: Install limit switches on various mechanical equipment to ensure that mechanical components (such as the slider of a press, the door of an elevator, etc.) do not exceed the safe operating range. For example, preventing a robotic arm from moving beyond its designed work area.

- Elevator control system: Limit switches are used during elevator door operation to ensure that the elevator can start only after the door is completely closed, thereby ensuring passenger safety.

- Automated production lines: Limit switches are used on automated production equipment to precisely control the position of machinery during production, such as on an assembly line to ensure correct placement of components.

- Traffic control equipment: In the control of railway signaling systems and highway obstacles (such as fences, toll station railings), limit switches are used to monitor and control the opening and closing status of railings.

- Household and Commercial Equipment: Use limit switches in household appliances and commercial equipment such as washing machine lids, commercial oven doors, etc. to ensure that the appliance only operates when the lid or door is fully closed.

- Stage technology: Use limit switches in stage scenery changes and lighting lifting mechanisms to ensure safe operation of equipment and avoid accidents.

- Agricultural machinery: Limit switches are used in agricultural machinery such as harvesters and plant protection drones to monitor the position of mechanical components and ensure that the machinery works within a predetermined operating range.

FAQ

What is a panel door limit switch?

Panel door limit switches are electrical switches used to monitor and control the position of specific components on mechanical equipment, such as doors or covers, ensuring that they move within predetermined limits.

How do panel door limit switches work?

This type of switch senses the position of a mechanical component through a movable arm or rod (stick). When the component moves and triggers the contact rod, the internal electrical contact points will close or open, thereby controlling the on and off of the circuit and realizing its control function.

What factors should be considered when selecting a panel door limit switch?

Consideration should be given to the switch’s electrical parameters (current and voltage), mechanical characteristics (actuation force and travel), installation method, operating environment (such as temperature, humidity), as well as the product’s durability and certification standards.

What types of panel door limit switches are there?

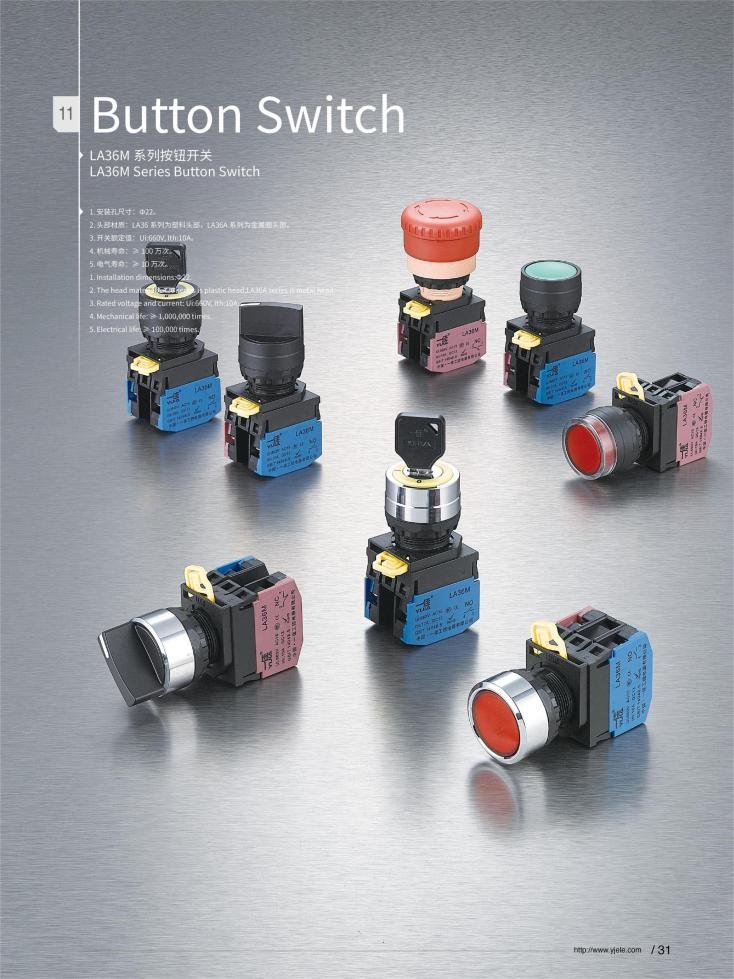

There are many types of limit switches, including mechanical, electromagnetic, photoelectric, etc. Different types are suitable for different environments and accuracy requirements.

How to install panel door limit switch?

During installation, it is necessary to ensure that the position of the switch can be accurately triggered by mechanical components, and the switch should be fixed firmly and reliably to prevent malfunction due to vibration or impact.

What are the common faults of panel door limit switches?

Common faults include poor contact, stuck contact rods, electrical faults (such as short circuit or open circuit), and damage caused by environmental factors (such as corrosion, overheating).

How to maintain and inspect panel door limit switches?

Regularly check whether the mechanical part of the switch is flexible and whether the electrical contact is good. Clean the switch to prevent the accumulation of dust and dirt that may cause malfunction. Perform regular maintenance according to manufacturer’s instructions.