Relay Switch

- Red mechanical indicator: It can intuitively judge whether the relay is attracted.

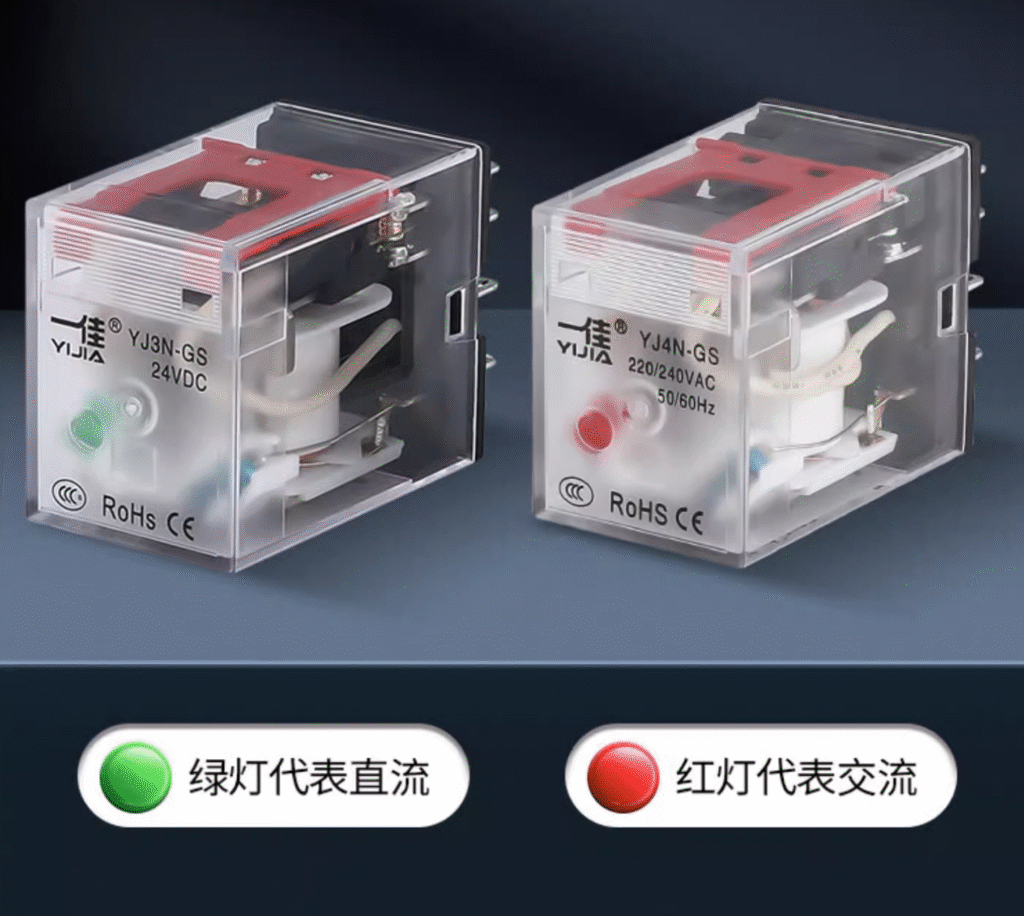

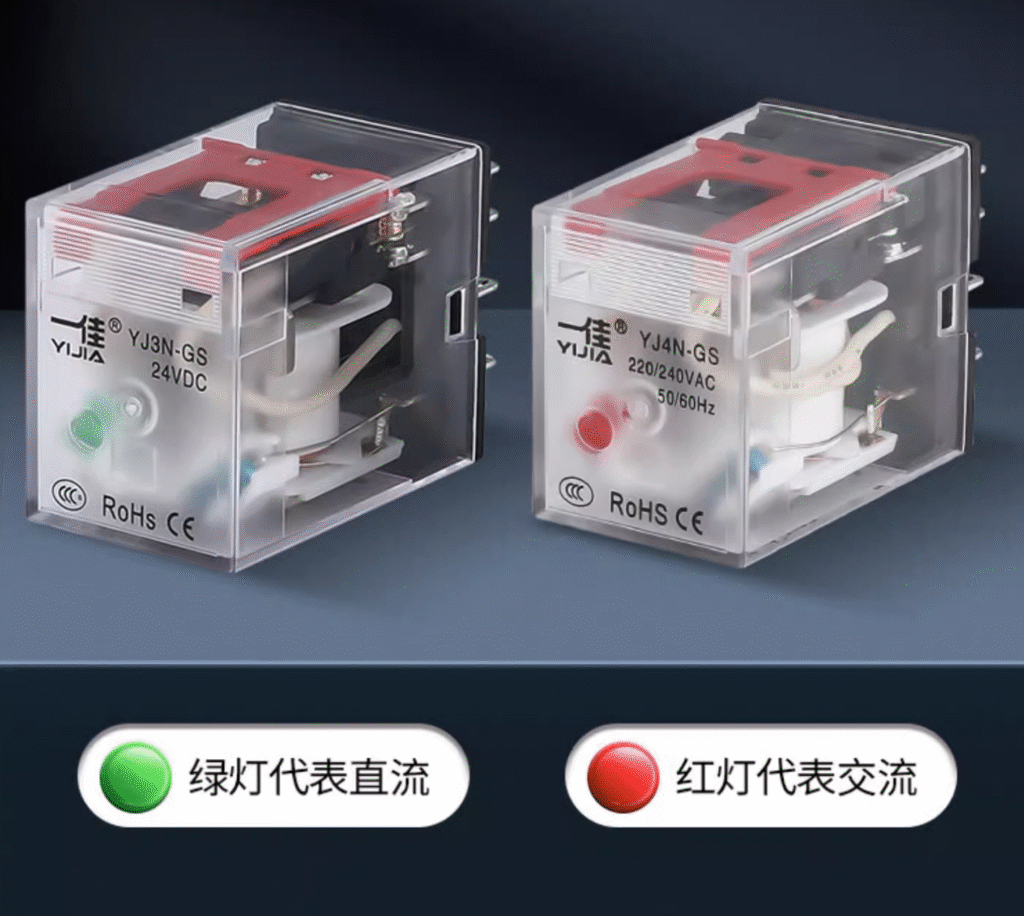

- LED signal lamp: It can judge the AC or DC coil, and judge whether the coil is energized.

- Low power electromagnetic relay rated load: AC240V/DC28V, 5A.

- High power electromagnetic relay rated load: AC240V/DC28V, 10A.

- Mechanical life: 40,000,000 times; Electrical life: 2 paris is 500,000 times, 3 paris and 4 paris is 200,000 times.

According to the color of the LED signal lamp, we can identify the AC coil or DC coil.

The type of coil is printed coil specifications, so the recognition is higher.

All products have mechanical indicators.

Relay Contact Specifications

| Item | Low Power – 2 Pairs | Low Power – 3 / 4 Pairs | High Power – 2 Pairs | High Power – 4 Pairs |

| Load Type | Resistive Load / Inductive Load (cosφ = 0.4, L/R = 7 ms) | Resistive Load / Inductive Load (cosφ = 0.4, L/R = 7 ms) | Resistive Load / Inductive Load (cosφ = 0.4, L/R = 7 ms) | Resistive Load / Inductive Load (cosφ = 0.4, L/R = 7 ms) |

| Contact Form | 2C | 3C / 4C | 2C | 4C |

| Contact Structure | Single Contact | Single Contact | Single Contact | Single Contact |

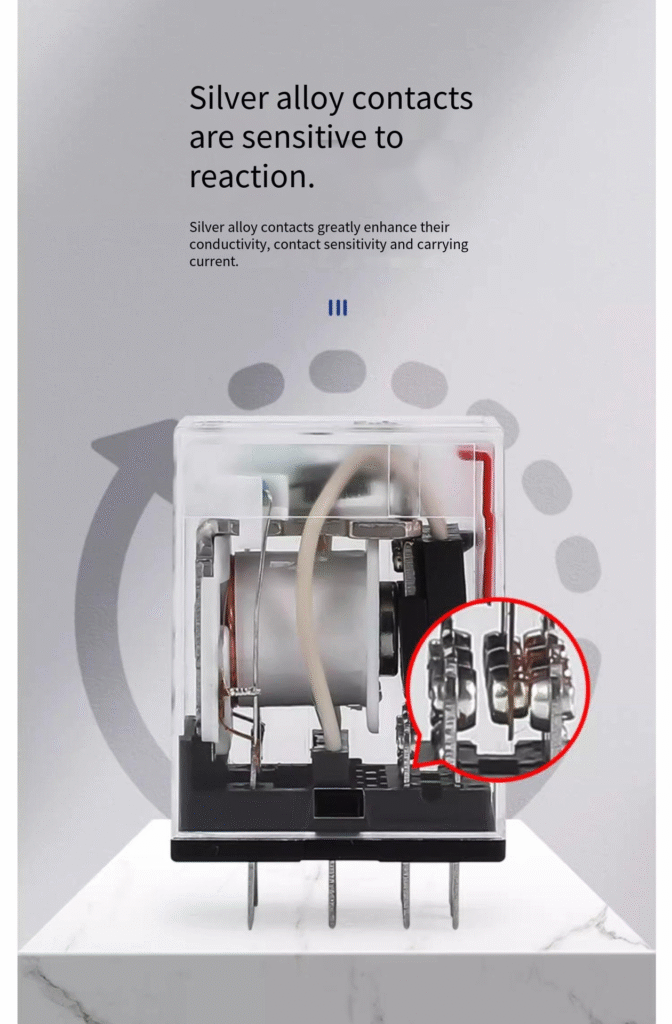

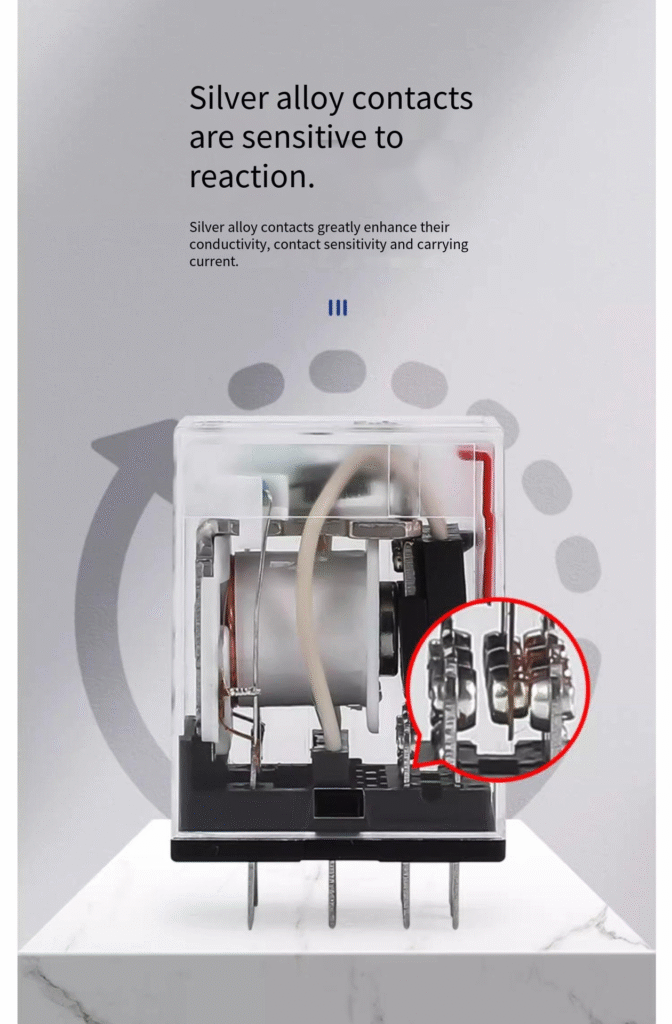

| Contact Material | Ag Alloy | Ag Alloy | Ag Alloy | Ag Alloy |

| Rated Load (Resistive) | AC 220V 5A | AC 220V 3A | AC 110V 10A | AC 110V 10A |

| DC 24V 5A | DC 24V 3A | DC 24V 10A | DC 24V 10A | |

| Rated Load (Inductive) | AC 220V 2A | AC 220V 0.8A | AC 110V 7.5A | AC 110V 7.5A |

| DC 24V 2A | DC 24V 1.5A | DC 24V 5A | DC 24V 5A | |

| Rated Current | 5A | 3A | 10A | 10A |

| Max Contact Voltage | AC 250V / DC 125V | AC 250V / DC 125V | AC 250V / DC 125V | AC 250V / DC 125V |

| Max Contact Current | 5A | 3A | 10A | 10A |

| Max Switching Capacity (Resistive) | 100 VA / 120 W | 660 VA / 720 W | 100 VA / 240 W | 100 VA / 240 W |

| Max Switching Capacity (Inductive) | 440 VA / 48 W | 176 VA / 36 W | 440 VA / 96 W | 440 VA / 96 W |

Intermediate Electromagnetic Relays: Principles, Applications, and Development Trends

Intermediate electromagnetic relays are essential components in electrical control systems and are widely used in industrial automation, power systems, transportation, and various control applications. As a professional relay manufacturer and supplier, YIJIA Relay provides intermediate electromagnetic AC relay switch with stable performance and customized solutions to meet different engineering and project requirements. Based on the principle of electromagnetic induction, these relays are mainly used for signal transmission, isolation, and conversion, playing a key role in ensuring the safe and reliable operation of complex electrical systems. With the continuous development of automation and intelligent equipment, intermediate electromagnetic relays are evolving toward higher performance, intelligent design, modular structure, environmental protection, and OEM/ODM customization, offering greater flexibility and value for system integrators and industrial users.

Working principle

The operation of the intermediate electromagnetic relay is based on the principle of electromagnetic induction. When the coil is energized, the changing current generates a magnetic field in the iron core, which attracts the armature (usually a movable iron core). As the current increases, the attraction also increases, causing the armature to be attracted towards the iron core. When the armature moves, it pushes the mechanical structure connected to the contact system, causing the normally closed contacts to open (i.e. separate) and the normally open contacts to close (i.e. connect). After the coil is powered off, the magnetic field disappears, and the armature returns to its original position under the action of the spring, and the contacts also return to their original state accordingly. This process is reversible, which means that when the coil is energized again, the contacts will change state again. For example, in a simple motor control circuit, the intermediate electromagnetic relay can control the on/off of the coil to achieve the connection and disconnection of the motor power supply, thereby controlling the start and stop of the motor.

Structural composition

3.1 Electromagnetic System

-Coil: A copper wire wrapped in insulating material wound around an iron core, which is a key component for generating a magnetic field. When a current is passed through a coil, a magnetic field is generated, and the strength of the magnetic field is related to factors such as the number of coil turns and the magnitude of the current. For example, in some situations where high control accuracy is required, increasing the number of coil turns is used to enhance the magnetic field and improve the reliability of relay operation.

-Core: Made of iron material with good magnetic permeability, it can concentrate magnetic field and enhance magnetic force, providing sufficient attraction for the movement of the armature. Iron cores made of different materials and structures can affect the performance of relays. For example, iron cores made of silicon steel sheets have lower hysteresis losses and can improve the efficiency of ac relay switches.

-Armature: It is a movable component that is attracted by a magnetic field and connected to a contact system. When it is attracted by a magnetic field, it drives the contact to move, achieving on/off control of the circuit. The quality and flexibility of the armature have a significant impact on the response speed of the relay, and a lightweight and smooth moving armature can make the relay move faster.

3.2 Contact System

-Normally open contact (NO): When the relay coil is not energized, it is in an open state. When the coil is energized, the armature moves and the normally open contact closes, thereby connecting the circuit. Normally open contacts are commonly used to control devices that require power to operate, such as motor start-up control.

-Normally closed contact (NC): When the relay coil is not energized, it is in a closed state. After the coil is energized, the armature moves, and the normally closed contact opens, cutting off the circuit. Normally closed contacts are commonly used in safety protection circuits. When an abnormality occurs in the system, the power supply is cut off by disconnecting the normally closed contacts to protect equipment safety.

-Common Terminal (COM): It is a common connection terminal for contacts, connected to normally open and normally closed contacts, to achieve different connection methods for circuits. For example, in a lighting control circuit, the common terminal can be connected to the power supply, and the normally open contacts can be connected to the lighting load. The on/off control of the lighting can be achieved by controlling the on/off of the relay coil.

3.3 Mechanical Transmission Components

-Spring: When the coil is powered off, it provides a resetting force for the armature and contacts, restoring them to their initial state. The elasticity coefficient and preload force of the spring need to be designed reasonably according to the working requirements of the relay to ensure that the contacts can be accurately and reliably reset.

-Connecting rod/transmission rod: transmits the motion of the armature to the contact point, achieving the opening and closing action of the contact point. The structure and connection method of the connecting rod/transmission rod will affect the mechanical performance of the relay. A firmly connected and flexibly transmitted connecting rod can ensure the accuracy and consistency of the contact action.

3.4 Auxiliary Structure

-Indicator lights: Some relays are equipped with LED indicator lights to display the power status of the coil. Through the indicator light, operators can intuitively understand the working condition of the relay, making it easier to detect faults in a timely manner. For example, in an automated production line, operators can quickly determine whether the control circuit of the equipment is working properly by observing the relay indicator lights.

-Manual operation button: used for testing or forcibly switching contact states, facilitating the operation of relays during debugging, maintenance, and other situations. The design of manual operation buttons should comply with ergonomic principles, be easy for operators to operate, and have good protective performance to prevent accidental operation.

-Terminal number: Clearly indicate the wiring positions of the coil and contacts, such as A1/A2 for coil terminals, 5/6/7/8 for normally open contact terminals, 1/2/3/4 for normally closed contact terminals, etc. Clear and accurate terminal numbering can greatly improve the efficiency and accuracy of wiring, reducing faults caused by wiring errors.

Classification method

4.1 Classification based on the number and type of contacts

- -Single group relay: With only one set of contacts, it is mainly used for simple circuit control, such as simple light switch control. By controlling the on/off of a single group relay, the light can be turned on or off.

- -Dual group relay: With two independent contact points, it is suitable for application scenarios that require two independent control groups, such as the control of car turn signals. The flashing of left and right turn signals can be controlled separately through dual group relays.

- -Multiple sets of relays: containing multiple sets of contacts, very useful in complex circuits, such as in automated production lines where multiple motors, sensors, and other devices need to be controlled simultaneously. Multiple sets of relays can achieve separate control of multiple devices through a set of control signals.

4.2 Classification based on coil driving method

- -Voltage driven type: requires continuous power supply to maintain the working state of the relay, suitable for stable power supply scenarios. For example, in home appliance control systems, voltage driven relays are often used to control the switching of appliances due to stable power supply.

- -Current driven type: Once current passes through the coil, magnetic force will be immediately generated and the contact will remain in a closed state. It is commonly used in situations where rapid response is required. In some high-speed data acquisition systems, in order to quickly capture signals, current driven relays are used to achieve rapid signal switching.

4.3 Classification based on contact capacity

- -Small capacity relay: suitable for controlling small loads such as LED lights, small motors, etc. The current and voltage that its contacts can withstand are relatively small, for example, controlling a small 5V LED light and using a small capacity relay can meet the requirements.

- -Large capacity relay: used to control high current and high voltage loads, such as air conditioning compressors, large motors, etc. The contacts of high-capacity relays are designed with special materials and structures to withstand high currents and voltages, ensuring reliability and safety when controlling high-power equipment.

4.4 Classification based on action time characteristics

- -Instantaneous action relay: When powered on or off, the contacts immediately act, suitable for situations that require quick switching. For example, in computer control systems, instantaneous action relays are often used to achieve fast signal switching in order to ensure fast data transmission and processing.

- -Delay action relay: There is a certain delay after power on or off, suitable for loads that require delayed start-up or shutdown. In some lighting systems, in order to avoid inconvenience caused by the lights immediately turning off after personnel leave, delay action relays are used to delay the lights for a period of time before turning off again after personnel leave.

4.5 Classification based on protection level

- -Ordinary protection level relay: Suitable for general indoor environments, it has a certain degree of protection against dust, moisture, etc., but the protection performance is relatively weak. In ordinary electrical control systems such as homes and offices, ordinary protection level relays can meet the requirements.

- -Special protection level relays: such as waterproof, dustproof, explosion-proof, etc., suitable for special environments such as outdoor, humid environments, industrial production, etc. In environments with flammable and explosive gases such as chemical plants, explosion-proof intermediate electromagnetic relays must be used to ensure safe production; In outdoor streetlight control systems, waterproof and dustproof relays are used to adapt to harsh natural environments.

Application Fields

5.1 Industrial Automation Field

In automated production lines, intermediate electromagnetic relays play a crucial role. It can convert a control circuit into multiple parallel control circuits, increase the number of contacts, and thus expand the capabilities of the control circuit. By controlling the opening and closing of various types of electric motors, actuators, cylinders, magnetic valves, and other electronic control components, intermediate electromagnetic relays make automated production lines more efficient, flexible, and reliable. For example, in the automotive manufacturing production line, intermediate electromagnetic relays can control the movement of robotic arms, the start and stop of material conveyors, etc., achieving automated assembly of automotive components, improving production efficiency and product quality.

5.2 Civil Electrical Field

Intermediate electromagnetic relays also play an important role in household and daily life scenarios. The functions of power on/off, timing, temperature control, etc. in household appliances often rely on the support of intermediate electromagnetic relays. For example, temperature control in household refrigerators is achieved by controlling the start and stop of the compressor through an intermediate electromagnetic relay to maintain stable temperature inside the refrigerator; Program control in washing machines, using intermediate electromagnetic relays to switch between different washing modes; The timed cooking function in the rice cooker is also controlled by an intermediate electromagnetic relay to regulate the power on time of the heating element.

5.3 Power system field

In the power system, intermediate electromagnetic relays are widely used in power control and protection systems. It can accurately control the operating status of power grid equipment, monitor abnormal situations, and promptly alarm or take protective measures. For example, in substation automation systems, intermediate electromagnetic relays can control the opening and closing of circuit breakers, achieving switching and protection of power lines; In the generator control device, it is used to regulate the output voltage and frequency of the generator to ensure the stable operation of the power system.

5.4 Transportation field

In the field of transportation, intermediate electromagnetic relays also play an important role. It can be used to control traffic facilities such as signal lights, electric gates, railway signal equipment, etc., to ensure the normal operation of transportation. For example, in railway signal systems, intermediate electromagnetic relays ensure the safe operation of trains by controlling the display of signals and the switching of switches; In the urban traffic signal control system, the use of intermediate electromagnetic relays to achieve timed switching of signal lights improves the efficiency and safety of the transportation system.

5.5 Security Control Field

Intermediate electromagnetic relays have also been widely used in various types of security alarm control and security monitoring systems. It can tightly connect the various subsystems of the security system together, achieving centralized monitoring and alarm functions. For example, in building security systems, intermediate electromagnetic relays can be connected to access control systems, surveillance cameras, anti-theft alarm devices, etc. When abnormal situations occur, alarm signals can be sent out by controlling the alarm device, and relevant information can be transmitted to the monitoring center, providing important security for people’s lives.

Development Trends

6.1 High performance

With the rapid development of industrial automation and power systems, the performance requirements for intermediate electromagnetic relays are also increasing. High performance intermediate electromagnetic relays require higher operating speed, more stable performance, and smaller size. At the same time, it is necessary to improve the overload capacity, durability, and reliability of the intermediate electromagnetic relay to meet the long-term stable operation requirements in complex environments. For example, the use of new magnetic materials and optimized electromagnetic structure design can improve the operating speed and sensitivity of relays; By improving the contact material and manufacturing process, the arc resistance and wear resistance of the relay are enhanced, and its durability and reliability are improved.

6.2 Intelligence

With the development of the Internet of Things and intelligent technology, the intelligence of intermediate electromagnetic relays has become an important development trend. Intelligent intermediate electromagnetic relays can achieve remote control, status monitoring, fault diagnosis and other functions, improving the automation and intelligence level of equipment. Through the integration of sensors, microprocessors, and other technologies, intelligent intermediate electromagnetic relays can monitor and control the status of circuits in real time. When abnormal situations are detected, timely alarms are issued and corresponding protective measures are taken to improve the reliability and safety of the system. For example, in smart factories, intelligent intermediate electromagnetic relays can communicate with the upper computer through a network to achieve remote monitoring and control, improving the efficiency of production management.

6.3 Modularization

In order to facilitate use and reduce costs, modularization of intermediate electromagnetic relays has become a development trend. Modular intermediate electromagnetic relays can integrate multiple contacts into one module, allowing users to choose different module combinations as needed to achieve different control functions. This modular design can reduce production costs, shorten production cycles, and facilitate user installation and maintenance. For example, in some large electrical control systems, users can select intermediate electromagnetic relay modules with different numbers and types of contacts according to their actual needs, and quickly build control circuits that meet the requirements.

6.4 Environmental Protection

With the continuous improvement of environmental awareness, the environmental performance requirements for intermediate electromagnetic relays are also increasing. Environmentally friendly intermediate electromagnetic relays require the use of eco-friendly materials and processes to reduce environmental pollution. At the same time, it is necessary to optimize product design, reduce energy consumption and heat loss, and improve energy efficiency. For example, adopting lead-free soldering technology, recyclable materials, etc., to reduce the emission of harmful substances to the environment; By optimizing coil design and heat dissipation structure, the energy consumption and heat generation of relays can be reduced, achieving energy conservation and environmental protection.

6.5 Customization

With the diversification of application requirements, customization of intermediate electromagnetic relays has also become a development trend. Different industries and users have different requirements for the performance, structure, size, and other aspects of intermediate electromagnetic relays. Customized intermediate electromagnetic relays can be designed and produced according to the special needs of users to meet personalized application scenarios. For example, in some special medical and aerospace equipment, it is necessary to customize intermediate electromagnetic relays with special specifications and performance to meet their strict technical requirements.

7、 Conclusion

As an important component in the field of electrical control, the intermediate electromagnetic AC relay switch has undergone continuous development and evolution over the past century. From initially simply increasing the number and capacity of contacts, to now achieving precise control of multiple functions in complex electrical systems, it plays an irreplaceable role in various fields. Through in-depth exploration of its working principle, structural composition, classification methods, application fields, and development trends, we can see that the technology of intermediate electromagnetic relays continues to advance and their application scope continues to expand. In the future, with the continuous development of technology, intermediate electromagnetic relays will continue to develop towards high performance, intelligence, modularity, environmental friendliness, and customization, making greater contributions to promoting the development of industrial automation, power systems, transportation, security and other fields. At the same time, relevant researchers and engineering technicians should continuously pay attention to its development trends, strengthen technological innovation, meet the growing application demands, and promote the further improvement and application expansion of intermediate electromagnetic relay technology.

FAQ

What is an AC relay switch?

An AC relay switch is an electromechanical or solid-state device that uses a low-power control signal to open or close an alternating-current circuit through internal contacts.

How does an ac relay switch work?

When AC voltage energizes the relay coil, it generates a magnetic field that pulls a movable armature, changing the state of the contacts to either complete or break the load circuit.

What are the main components of an relay switch?

Key components include a coil, movable armature, return spring, and contact set, which together perform the switching function between the control circuit and the AC load.

Are pushbutton switches suitable for industrial use?

Yes, push button switches are widely used in industrial applications. They are known for their durability, reliability, and ability to handle high currents or voltages. Industrial-grade switches typically have rugged construction and meet specific industry standards for performance and security.

How to install push button switch?

The installation process may vary depending on the specific switch and application. Generally speaking, push button switches can be panel mounted or PCB mounted. Panel mount switches require a hole in the control panel or housing, while PCB mount switches are soldered directly to the printed circuit board.

What is the function of an AC relay switch in electrical control?

The primary function is to safely control higher-voltage or higher-current AC loads—such as motors, heaters, and lighting—using a low-power control signal from a thermostat, controller, or PLC.

Can the product and packaging be customized?

Yes. We have customized a lot for customers before. Includes different button shapes, colors and terminals. Custom switches can be tailored to specific brand or application requirements.

Regarding the customization of packaging, we can put your logo or other information on the packaging, no problem. It’s just that this will incur some additional costs.

Can you provide samples? Is the sample free?

Yes, we can provide samples. But you need to pay for the freight. If the sample needs more quantity, we will charge the sample fee.

Where are AC relay switches commonly used?

They are widely used in HVAC systems, industrial machinery, home automation, motor starters, and protection circuits that need reliable on–off control and sequencing.