Precautions for connecting limit switches

The purpose of limit switch connection

The purpose of limit switch connection is to control the movement or operation in mechanical equipment or systems, and to achieve automatic control and protection functions by detecting the preset position or state. Limit switches can help equipment automatically stop or switch operations when reaching a specified position, preventing mechanical damage or safety accidents caused by exceeding the set range. In addition, limit switches can also provide accurate position feedback during equipment operation to ensure the stability and reliability of the system. By connecting and using limit switches, production efficiency can be improved, human operating errors can be reduced, and the safety of equipment and operators can be guaranteed.

How to connect?

1. Determine the terminals: Most limit switches have three terminals: Normally Open (NO), Normally Closed (NC), and Common (COM). Before wiring, confirm the terminal markings of the switch.

2. Select the appropriate cable: Select a cable of appropriate specifications based on the voltage and current requirements of the device. Make sure the cable is long enough and can withstand the temperature and wear in the working environment.

3. Power-off operation: Before wiring, make sure the device is completely powered off to avoid the risk of electric shock.

4. Connect the Common (COM): Connect the power line or control line to the Common (COM) of the limit switch.

5. Connect the Normally Open (NO) or Normally Closed (NC):

- If you need to open the circuit when the limit switch is triggered, connect to the Normally Closed (NC).

- If you need to close the circuit when the limit switch is triggered, connect to the Normally Open (NO).

6. Fix the wiring: Use cable clamps or other fixing devices to fix the cable in place to prevent the cable from loosening or being damaged.

7. Check the connection: Carefully check all connection points to ensure that the wiring is secure and correct.

8. Power-on test: Restore power to the equipment and perform a functional test to ensure that the limit switch works properly when triggered.

The basic principle of limit switch connection

1. Mechanical action: The limit switch is usually installed on the moving part of the equipment. When the moving part reaches the predetermined position, the mechanical action of the limit switch is triggered. This action is usually achieved by a mechanical device such as a lever, button or roller.

2. Electrical contact conversion: When the limit switch is triggered, the electrical contacts inside it will be converted. There are two ways to convert the contacts:

- Normally open (NO) contacts: In the normal state, they are open. When the limit switch is triggered, the contacts are closed and the circuit is connected.

- Normally closed (NC) contacts: In the normal state, they are closed. When the limit switch is triggered, the contacts are open and the circuit is disconnected.

3. Signal transmission: The conversion of the limit switch contacts changes the circuit state, thereby transmitting a signal to the control system or drive device. For example, when the normally open contact is closed, a signal can be sent to start the next operation, or when the normally closed contact is open, a signal can be sent to stop the operation of the equipment.

4. Feedback and control: After the control system receives the signal from the limit switch, it will perform the corresponding operation. This may include stopping the motor, changing direction, starting an alarm or other control actions. In this way, the limit switch can provide accurate feedback of the equipment position and realize automatic control and protection of the equipment.

5. Safety guarantee: The connection principle of the limit switch also involves the safety protection function. When the equipment reaches a dangerous position or abnormal state, the limit switch can automatically cut off the power supply or sound an alarm to prevent equipment damage or personal injury.

Common ways to connect limit switches

1. Single-pole single-throw connection (SPST):

- Description: A single-pole single-throw limit switch has only one input and one output, suitable for simple switch control.

- Application: Used for basic circuit control, such as simple switch opening and closing operations.

2. Single-pole double-throw connection (SPDT):

- Description: A single-pole double-throw limit switch has one input and two outputs, which can switch between two circuits.

- Application: Used in situations where switching between two states is required, such as selecting different operating modes or paths.

3. Double-pole double-throw connection (DPDT):

- Description: A double-pole double-throw limit switch has two inputs and two outputs, which can control the switching of two independent circuits at the same time.

- Application: Used in complex control systems that require multiple circuits to be switched at the same time.

4. Parallel connection:

- Description: Multiple limit switches are connected in parallel to the same circuit, and any one switch being triggered will change the circuit state.

- Application: Used in situations where redundant protection or multiple position detection is required, such as multiple door limit switches.

5. Series connection:

- Description: Multiple limit switches are connected in series to the same circuit, and all switches must be triggered to change the circuit state.

- Application: Used in safety interlocks or situations where multiple conditions must be met to operate, such as multi-point protection of machines.

6. Three-pole double-throw connection (3PDT):

- Description: The three-pole double-throw limit switch has three inputs and three outputs, which can control the switching of three independent circuits at the same time.

- Application: Used in more complex control systems where multiple circuits need to be switched at the same time.

7. Jumper connection:

- Description: Jumper limit switches in a circuit to bypass certain parts of the circuit in specific positions or conditions.

- Application: Used for temporary or conditional circuit connections, allowing the circuit path to be changed under specific conditions.

Notes on connection

- Ensure power-off operation: Before connecting the limit switch, you must ensure that the device is completely powered off to avoid the risk of electric shock and equipment damage.

- Choose the right switch: According to the specific application requirements, select the appropriate limit switch model and specifications to ensure that its rated voltage, current and environmental adaptability meet the requirements.

- Check the terminals: Carefully read the wiring diagram or instructions of the limit switch to confirm the function of each terminal (such as normally open NO, normally closed NC, common terminal COM) to avoid wrong connection.

- Use the right cable: Select the appropriate specification and type of cable to ensure that it can withstand the required current and voltage, and is durable and wear-resistant.

- Fix the wiring: Ensure that all connecting wires are firmly fixed to the terminals, and use cable clamps or other fixings to prevent the cables from loosening or being damaged.

- Avoid short circuits: Ensure that there are no exposed wires between the terminals to avoid failures caused by poor contact or short circuits.

- Regular inspection and maintenance: Regularly check the connection status and function of the limit switch to ensure that it is working properly. Cables that are found to be worn or loose should be replaced or re-fixed in time.

- Protective measures: In harsh or corrosive environments, use a protective cover or choose a waterproof and dustproof limit switch to extend its service life.

- Correct wiring method: Follow standard electrical wiring specifications to ensure that all lines are neat and orderly to avoid cross interference and signal attenuation.

- Refer to manufacturer guidance: Follow the installation and connection guidelines provided by the limit switch manufacturer to ensure that all operations meet the specifications.

- Functional test: After the connection is completed, perform a functional test to ensure that the limit switch can work normally under the preset conditions and verify whether its protection and control functions are effective.

FAQ

1. What is a limit switch?

A limit switch is a switch used to detect mechanical position and travel. It controls the opening and closing of the circuit by triggering the mechanical parts of the switch to achieve automatic control and protection of the equipment.

2. What are the common types of limit switches?

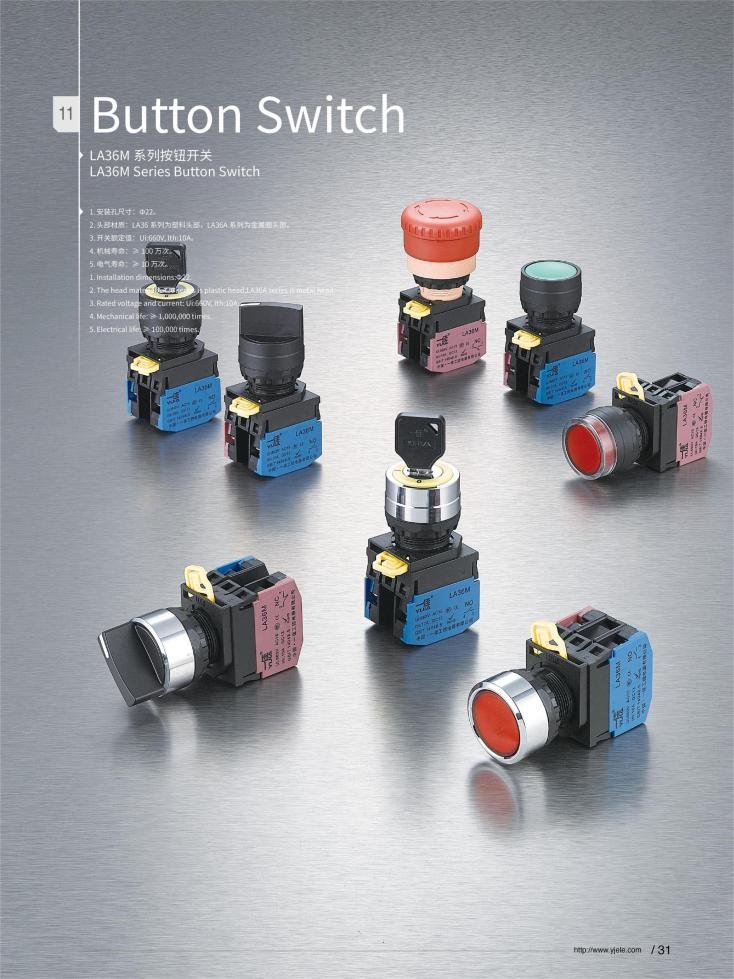

Common types of limit switches include micro limit switches, roller lever limit switches, button limit switches, and rotary limit switches.

3. What are the main applications of limit switches?

Limit switches are widely used in industrial automation equipment, lifting machinery, conveyor systems, door and window controls, household appliances, and other occasions that require position detection and travel control.

4. How to choose a suitable limit switch?

The following factors need to be considered when selecting a limit switch: operating voltage and current, environmental conditions (such as temperature, humidity, dust, etc.), mechanical strength, response speed, and contact form (NO/NC).

5. How to wire a limit switch?

When wiring, determine the wiring terminals (COM, NO, NC), select the appropriate cable, and ensure power-off operation. Connect the power line or control line to the corresponding terminal, and perform a functional test after fixing the wiring.

6. What are the common connection methods of limit switches?

Common connection methods include single-pole single throw (SPST), single-pole double throw (SPDT), double-pole double throw (DPDT), parallel, series and jumper connections.

7. What do the NO and NC of the limit switch contacts mean?

NO (Normally Open) means normally open contacts. The contacts are open in the normal state and closed when the switch is triggered. NC (Normally Closed) means normally closed contacts. The contacts are closed in the normal state and open when the switch is triggered.

8. What should be paid attention to when using limit switches?

It is necessary to ensure power-off operation, select appropriate switches and cables, fix wiring, avoid short circuits, conduct regular inspections and maintenance, take protective measures, refer to manufacturer guidance and perform functional tests.

9. What are the common causes of limit switch failure?

Common failure causes include mechanical wear, oxidation or ablation of electrical contacts, environmental factors (such as moisture, dust), and loose or broken wiring.

10. How to extend the service life of limit switches?

Regular inspection and maintenance, select durable and environmentally adaptable limit switches, ensure correct wiring and fixing, use protective measures such as protective covers, and avoid overloading and frequent operation.