FAQs

FAQ

Frequently Asked Question

A push button switch is an electrical component designed to be pressed or pushed by the user to make or break an electrical circuit. It is commonly used in various applications to control electric current.

Tactile pushbutton switches are designed to provide tactile feedback when pressed. They usually have a small bump or dome under the button, allowing the user to feel a physical “click” or resistance when the switch is actuated.

To select the appropriate pushbutton switch, consider the required voltage and current ratings, circuit type (AC or DC), environmental conditions (e.g., humidity, temperature), installation requirements, and desired function (momentary, latching, illuminated, etc.).

Yes, push button switches are widely used in industrial applications. They are known for their durability, reliability, and ability to handle high currents or voltages. Industrial-grade switches typically have rugged construction and meet specific industry standards for performance and security.

The installation process may vary depending on the specific switch and application. Generally speaking, push button switches can be panel mounted or PCB mounted. Panel mount switches require a hole in the control panel or housing, while PCB mount switches are soldered directly to the printed circuit board.

Certain pushbutton switches are designed to withstand outdoor environments, including exposure to moisture, dust, and temperature changes. Look for a switch with the appropriate IP rating, or consult the manufacturer for a switch specifically designed for outdoor applications.

Yes. We have customized a lot for customers before. Includes different button shapes, colors and terminals. Custom switches can be tailored to specific brand or application requirements.

Regarding the customization of packaging, we can put your logo or other information on the packaging, no problem. It’s just that this will incur some additional costs.

Yes, we can provide samples. But you need to pay for the freight. If the sample needs more quantity, we will charge the sample fee.

Welcome! But please let me know first and check your country. If you want any other kind of cooperation, please feel free to contact us.

Comprehensive Guide to Button Switches

- What is a button switch?

Button switch is a type of switch that uses buttons to push the transmission mechanism, causing the moving and stationary contacts to switch on or off and achieve circuit switching. It is a structurally simple and widely used master electrical device, used in electrical automatic control circuits to manually issue control signals to control contactors, relays, electromagnetic starters, etc. Button switches are usually composed of button caps, reset springs, static contacts, moving contacts, and a housing, etc. They are generally made in a composite form, with a pair of normally closed contacts and normally open contacts.

- How does the button switch work?

The working principle of button switches is based on the changes in the on/off state of the contacts. Under normal circumstances, normally open contacts are open and normally closed contacts are closed. When the button is pressed, the moving contact contacts or separates from the stationary contact under the action of the transmission mechanism, thereby changing the on/off state of the circuit. After releasing the button, the reset spring returns the moving contact to its original state. For example, when a normally open button switch is pressed, the contacts close and the circuit conducts; After releasing, the contact opens and the circuit is disconnected. The normally closed button switch is the opposite. When pressed, the contacts open, and when released, the contacts close.

- How to connect the button switch?

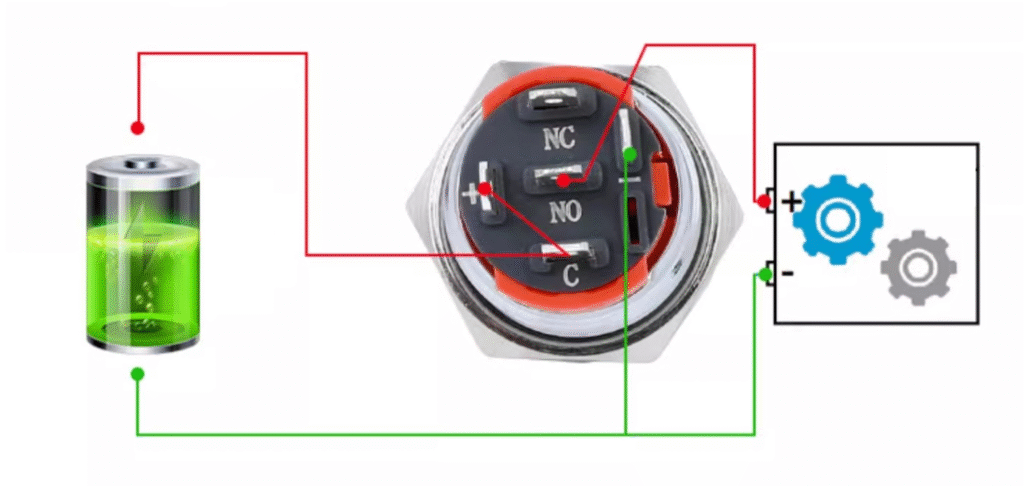

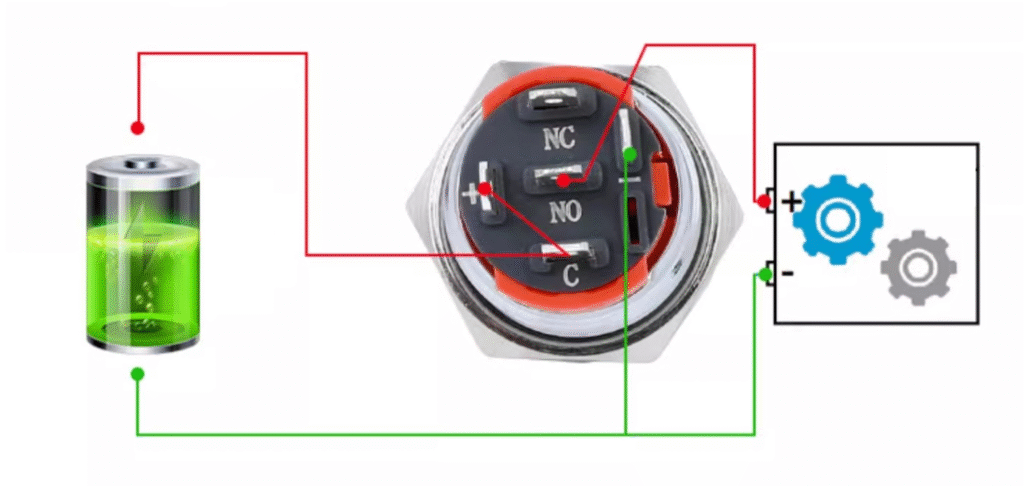

The connection methods of button switches mainly include series connection and parallel connection. Series connection is to place the button switch in the middle position of the circuit, and control the on/off of the circuit through its switch state. The specific steps are: connect the positive terminal of the power supply to one terminal of the button switch, connect the other terminal of the button switch to one terminal of the load, and connect the other terminal of the load to the negative terminal of the power supply. Parallel wiring is the process of placing a button switch on two branches of a circuit and controlling the on/off state of one branch based on its switch status. When connecting, connect the positive terminal of the power supply to one terminal of the load, connect the other terminal of the load to one terminal of the button switch, and connect the other terminal of the button switch to the negative terminal of the power supply. In practical applications, suitable wiring methods can be selected according to specific needs, such as implementing multi-point control through parallel wiring and cascading control through series wiring.

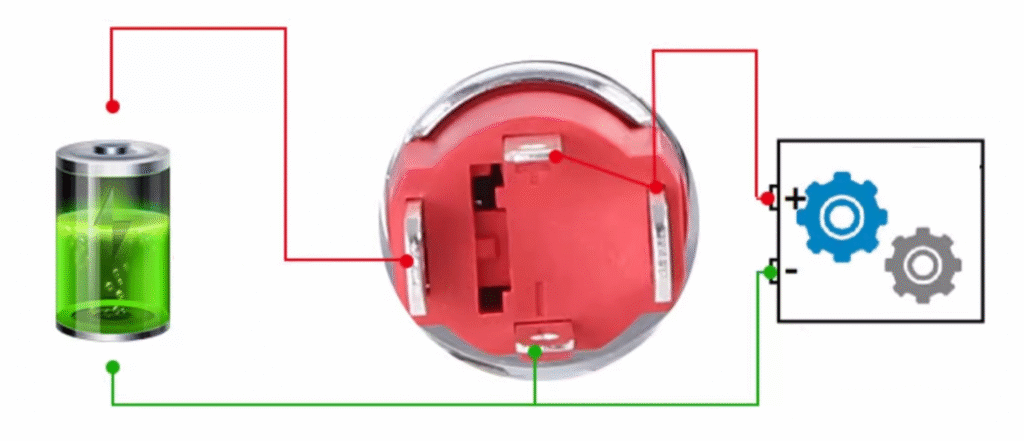

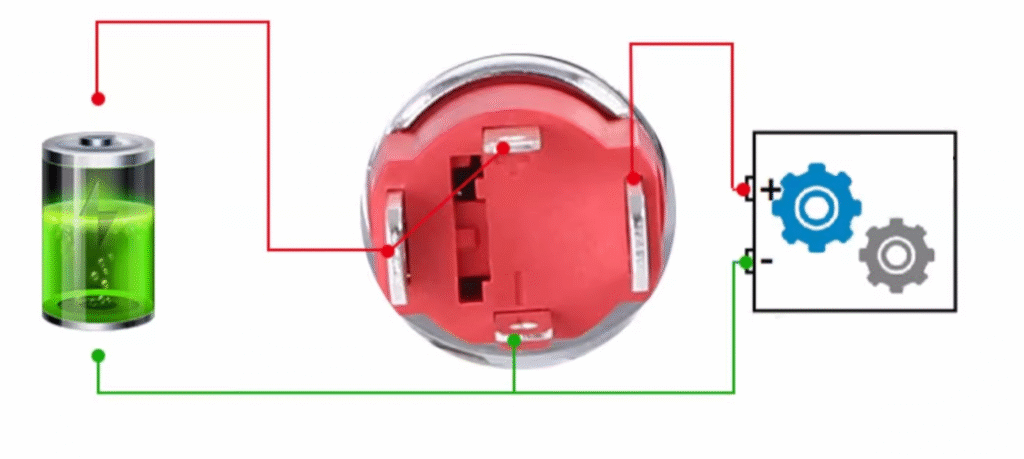

YIJIA introduces the wiring diagram of 4PIN button switch with 10A current

(1)、 The LED light will turn on when pressed

Self locking button effect: When the button is pressed, the light will turn on and the device will not be powered off after being released; Press the button again, the light will turn off and the device will be powered off.

Self resetting button effect: Press and hold the button, the light will turn on while the device is powered on. Release the button and the light will turn off while the device is powered off.

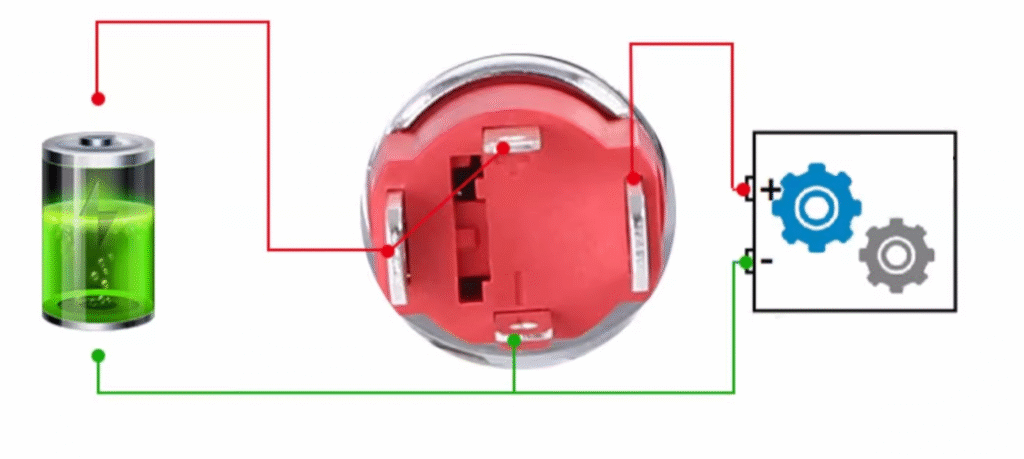

(2)、 The LED light stays on all the time

Self locking button effect: Press the button to power on the device, release it and keep it powered off. Press the button again to power off the device.

Self resetting button effect: Press and hold the button to power on the device, release it to power off the device.

YIJIA will introduce you to two different wiring methods for 5-pin button switches, with a current of 5A

(1)、 The LED light will turn on when pressed

Self locking button effect: When the button is pressed, the light will turn on and the device will not be powered off after being released; Press the button again, the light will turn off and the device will be powered off.

Self resetting button effect: Press and hold the button, the light will turn on while the device is powered on. Release the button and the light will turn off while the device is powered off.

(2)、 The LED light stays on all the time

Self locking button effect: Press the button to power on the device, release it and keep it powered off. Press the button again to power off the device.

Self resetting button effect: Press and hold the button to power on the device, release it to power off the device.

- Where is the button switch used?

Button switches are widely used in various fields. In household appliances such as televisions, speakers, washing machines, etc., users can turn on the power, select functions, or adjust settings by pressing the corresponding buttons. In industrial equipment, button switches are required for the start/stop button, indicator light on/off, and valve opening on the machine. In transportation, drivers of cars, trains, and other vehicles can control various functions of the vehicle, such as lighting, air conditioning, and sound systems, by pressing different buttons inside the vehicle. In medical equipment, button switches are also used for instruments and equipment on the operating table, hospital bed call systems, and emergency equipment on ambulances.

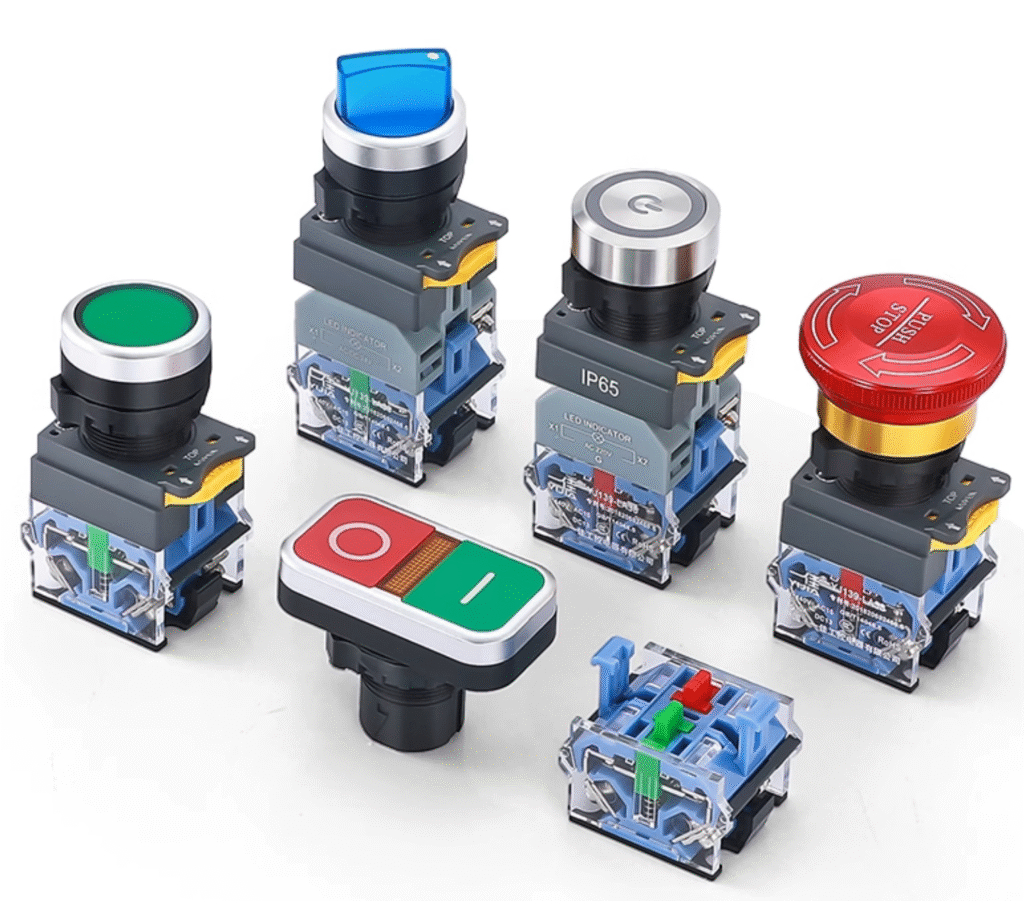

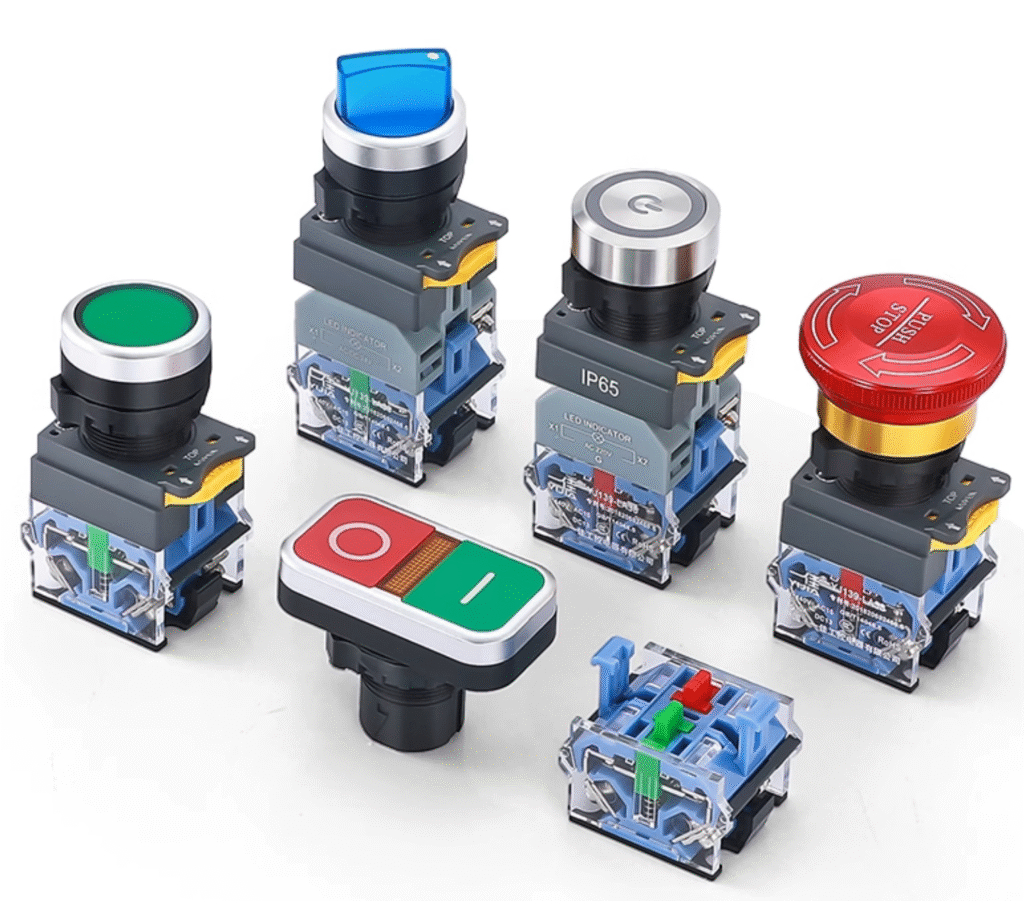

- What are the different types of button switches?

- Ordinary button type: a common type of button switch with simple operation.

Mushroom head style: The button cap is relatively large and is usually used for emergency stops and other situations that require clear identification and operation.

Self locking: automatically maintains the closed position when pressed, and can only be opened after power failure, suitable for situations that require long-term maintenance of the state.

Self resetting type: It operates when pressed and automatically resets when released, making it the most common type of button switch.

- Rotary handle type: Control the on/off of contacts by rotating the rotary handle.

- With indicator light type: The button is equipped with a signal light, which is not only used to issue operation commands, but also serves as a signal indicator.

- Symbolic with lights: On the basis of indicator lights, symbol identification is added to more intuitively display the switch status.

Key type: operate by inserting and rotating a key, which can prevent accidental operation or be operated by a dedicated person.

- Protective: With a protective shell, it can prevent mechanical damage to the internal button parts or human contact with live parts.

Explosion proof: It can be used in places containing explosive gases and dust without causing detonation.

Anti corrosion type: It can prevent the invasion of corrosive gases in the chemical industry.

Waterproof: With a sealed casing, it can prevent rainwater from entering.

Emergency: There is a red mushroom button protruding outward, which can be used to cut off power in case of emergency.

Open type: can be used for embedding and fixing on the panel of the switch board, control cabinet or console.

Chain type: It has multiple contacts that are interlocked with each other.

Knob type: Rotate the operating contact by hand, with two positions for on/off, usually panel mounted.

- What are the advantages of using button switches?

- Easy to operate: The button switch can achieve circuit on/off control through simple pressing or rotating actions, making it easy to operate.

Compact structure: Small in size, occupying less space, suitable for various compact installation environments.

- High reliability: Good contact between contacts, accurate action, and able to ensure stable circuit continuity.

- Diverse functions: Different types of button switches have different functions, such as self-locking, self resetting, with indicator lights, etc., which can meet various application needs.

Good safety: Some button switches have protective shells, waterproof, explosion-proof, anti-corrosion and other functions, which can ensure safe use in harsh environments.

- How to choose the appropriate button switch?

Select the type of button based on the usage scenario and specific purpose: for example, buttons embedded in the operation panel can be of the open type; Use indicator lights to display the working status; In very important occasions, to prevent unrelated personnel from operating incorrectly, it is advisable to use a key operated method; Corrosion resistant materials should be used in areas with corrosive gases.

According to the work status indication and requirements, select the color of the button or indicator light: for example, the start button can be white, gray, or black, with white being preferred and green also allowed; The emergency stop button should be selected in red; The stop button can be selected in black, gray, or white, with black being preferred and red also allowed.

Select the number of buttons according to the needs of the control circuit, such as single button, double button, and triple button.

Consider electrical parameters such as rated voltage, rated current, etc., to ensure that the button switch can meet the requirements of the circuit.

- Consider protection level: Choose the appropriate protection level based on the usage environment, such as waterproof, dustproof, explosion-proof, etc.

- What is the difference between momentary and latch button switches?

Instant button switch: establishes a circuit connection immediately when the button is pressed, and quickly disconnects the circuit when the button is released. It is commonly used in situations that require brief signal triggering, such as the start button of electronic devices, the reset button of counters, etc.

Lock button switch: allows users to change the switch state by pressing the button, and the state will remain until the button is pressed again. It is commonly used in situations where a state needs to be maintained for a long time, such as power switches and mode switching buttons on electronic devices.

- Is there any safety issue with the button switch?

The safety issues of button switches involve multiple aspects, including electrical safety, mechanical safety, and usage safety. Electrical safety issues may include current leakage, risk of electric shock, and fire caused by overload. Mechanical safety issues mainly include the durability, stability, and impact resistance of button switches. The use of safety issues mainly involves the dangers that users may encounter during use, such as electric shock, misoperation, etc. To ensure the safety of button switches, it is necessary to choose button switches with good insulation materials that meet relevant safety design standards, use overload protectors, consider adding sealing layers or using corrosion-resistant coatings during design to avoid applying excessive pressure or heavy objects to the button switches, follow correct operation and maintenance specifications during use, and regularly check the use of button switches.

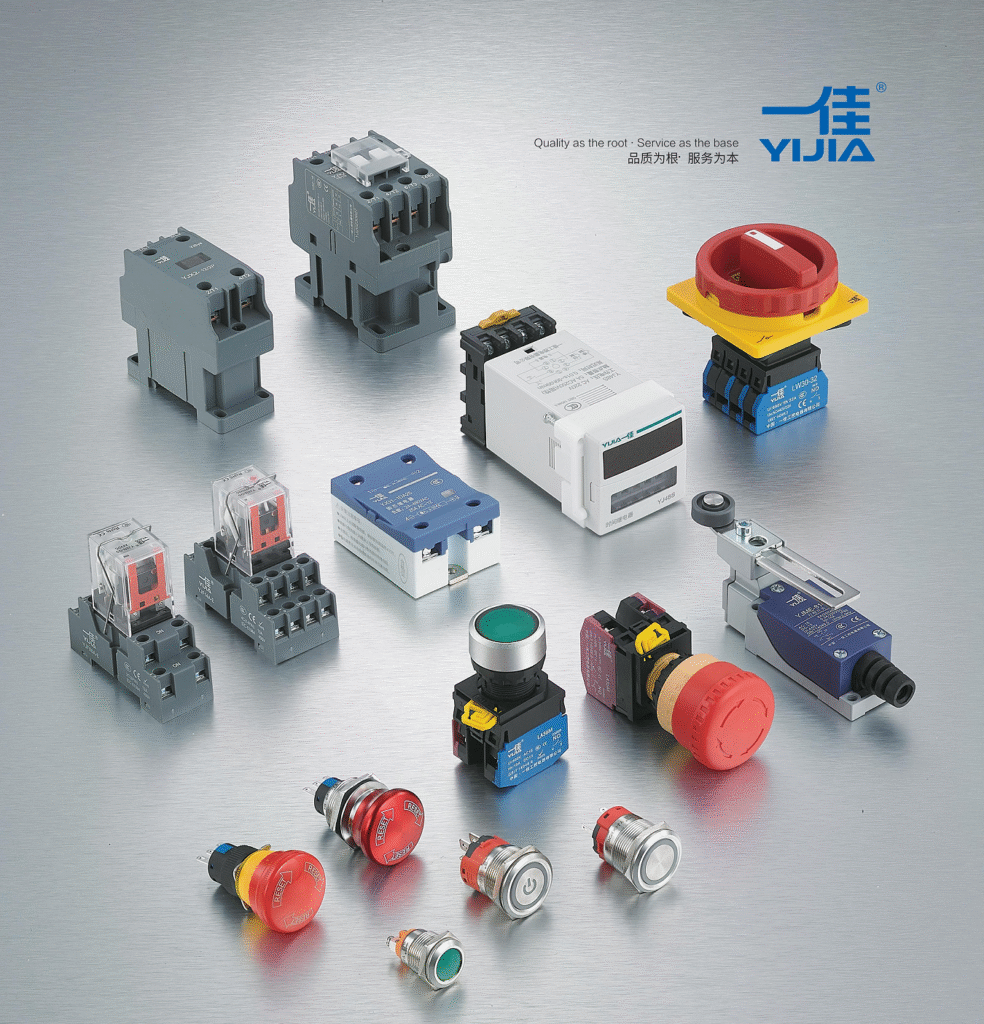

- What are some high-quality button switch brands?

The top ten brands in the 2025 button switch ranking are: Schneider、Legrand、DELIXI、Omron、CHNT、GELAN、FUTINA、TCL、GAMDER、IDEC、YIJIA。 These brands have high popularity and good reputation in the field of button switches, with reliable product quality and performance.

- The main differences between light button switches and regular button switches

The main difference between a light button switch and a regular button switch is that the light button switch is equipped with a signal light inside, which is not only used to issue operation commands, but also serves as a signal indicator. And ordinary button switches only have the function of controlling the on/off of the circuit. The button switch with lights can intuitively display the switch status through indicator lights of different colors, improving the convenience of operation.

- Description of self reset button switch

The self reset button switch is a button switch that operates when pressed and resets when released. It is used to connect and disconnect small current circuits, generally used in control circuits with AC/DC voltage below 440V and current less than 5A. When the button is pressed, the contacts close and the circuit conducts; After releasing the button, under the action of the reset spring, the contacts return to the disconnected state and the circuit is disconnected. The self reset button switch has the characteristics of simple structure, convenient operation, and high reliability, and is widely used in various electrical control circuits.

- Description of self-locking button switch

The self-locking button switch allows users to change the switch state by pressing the button, and the state will remain until the button is pressed again. It usually consists of buttons, locking mechanisms, movable contacts, and fixed contacts. When the button is pressed, the locking mechanism maintains the switch state. When the button is pressed again, the locking mechanism unlocks and the switch state returns. Self locking button switches are commonly used in situations where a state needs to be maintained for a long time, such as power switches and mode switching buttons in electronic devices.

What is an emergency stop button?

Introduction to Emergency Stop Button Switch

- Definition and Function

Emergency Stop Button is a fail safe control switch used to quickly cut off equipment power and stop equipment operation in emergency situations. It provides safety guarantees for machinery and equipment, aiming to avoid personnel injury or reduce existing hazards to machinery and work. When the device encounters an emergency problem and needs to be powered off immediately, pressing the emergency stop button can immediately disconnect the main control circuit, causing the device to stop running immediately and thus relieve the emergency situation.

- Appearance and identification

- Color: The actuator cap must be red and the background must be yellow for easy operation in emergency situations.

- Shape: Usually designed with a mushroom head for quick pressing, and some emergency stop buttons have a large execution surface that can be operated with the palm, fist, or even foot.

- Identification: Emergency stop signs should be posted at the locations where signs are provided to remind operators.

- Structure and Working Principle

Structure: The emergency stop button is usually designed with two emergency contacts, namely the normally open contact (NO) and the normally closed contact (NC). The normally closed contact is in a closed state under normal conditions and opens when the button is pressed; The normally open contact is in the open state under normal conditions and closes when the button is pressed (but in emergency stop buttons, normally open contacts are usually not used for primary control functions).

Working principle: The emergency stop button is connected in series with the control circuit of the device. When the button is pressed, the internal normally closed contacts are disconnected, which drives the motor control circuit to disconnect and stop the motor from running. The mechanical lock inside the button will lock directly and does not support automatic reset, but can be manually rotated for reset.

- Types and Applications

- Type: Common emergency stop buttons include push-pull buttons, push stop/pull release buttons, rotary buttons, etc. When pushing to stop, press the button to stop, only the key can release it.

Application: The emergency stop button is widely used in various fields such as industry, commerce, and public facilities, such as elevators, packaging machines, lifting equipment, various lathes, crushers, punching and shearing equipment, etc. A machine can also have multiple emergency stop buttons, depending on which part of the machine needs to be stopped.

- Safety and reliability

- Safety: The emergency stop button has a direct open circuit action device (forced disconnection device) on the NC contact to ensure reliable power cut-off in emergency situations. If the contact is stuck, the equipment cannot be stopped in harmful situations, so emergency stop buttons usually use NC contacts to improve safety.

Reliability: The emergency stop button must be guaranteed to be effective at all times. When the emergency stop device is activated, all other commands immediately become invalid, and the emergency stop function has the highest priority level. No other operation will be effective until the emergency stop device is manually reset.

- Installation and use

Installation: The installation position of the emergency stop button should be easy for operators to quickly access in emergency situations, and should avoid accidental operation. In certain environments, emergency stop buttons or emergency stop button covers with casings may be used to prevent accidental operation.

- Use: In emergency situations, press and lock the red mushroom head button switch or circular button switch; Use a safety lock to lock the emergency stop button protective cover (if necessary). In daily work, it is prohibited to use the emergency stop device as a machine shutdown device, as repeated and uninterrupted use of the emergency stop device will reduce its reliability.

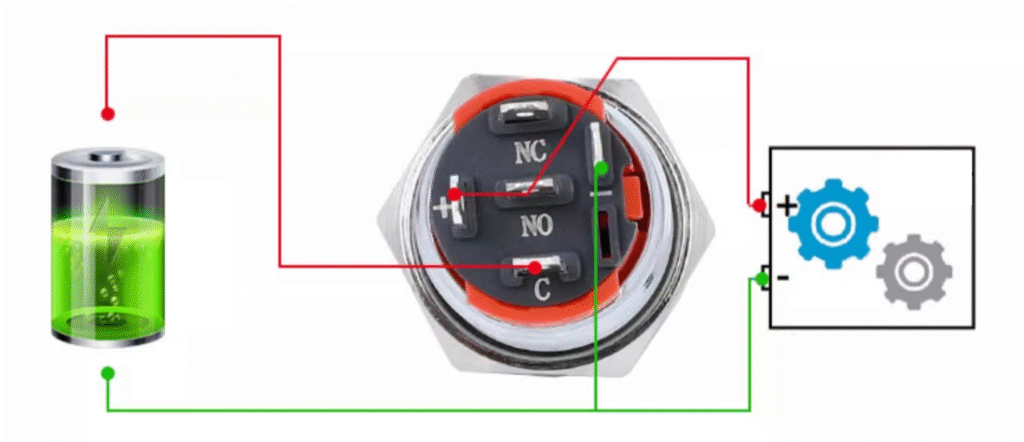

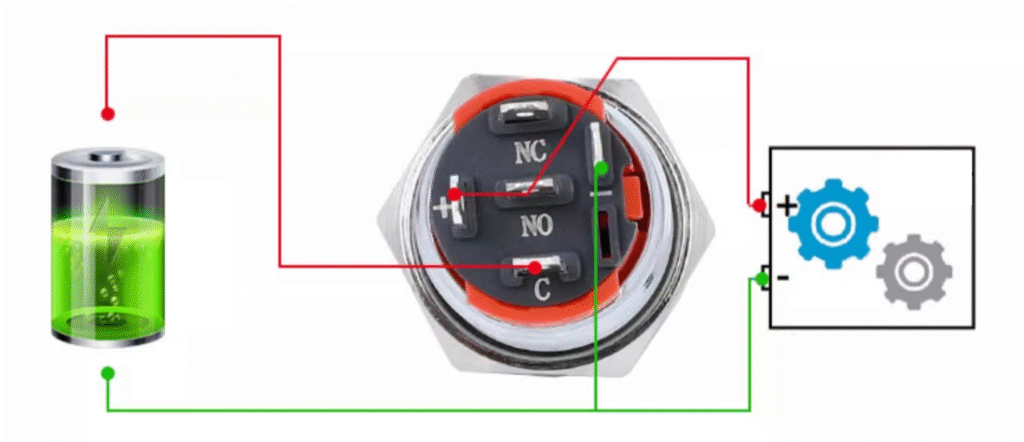

YIJIA will introduce to you the normally closed wiring method of the 3-pin emergency stop button, with a current of 5A

Normally closed wiring method

Power on the load, press the button to turn off the load.

The emergency stop button switch can be divided into three types according to the installation size

16mm/19mm/22mm emergency stop button

Among them, the emergency stop buttons of 19MM and 22MM are the most commonly used, usually used for automatic equipment or car charging poles.

The voltage of the metal emergency stop button switch can be 12V, 110V, 120V, 220V, etc., depending on the equipment used.

If used for mechanical equipment, it is basically a 12 volt emergency stop button. If used in North America, it is basically a 120 volt emergency stop button. If used in China or car charging stations, it is basically a 220V emergency stop button.