Metal Signal Lamp

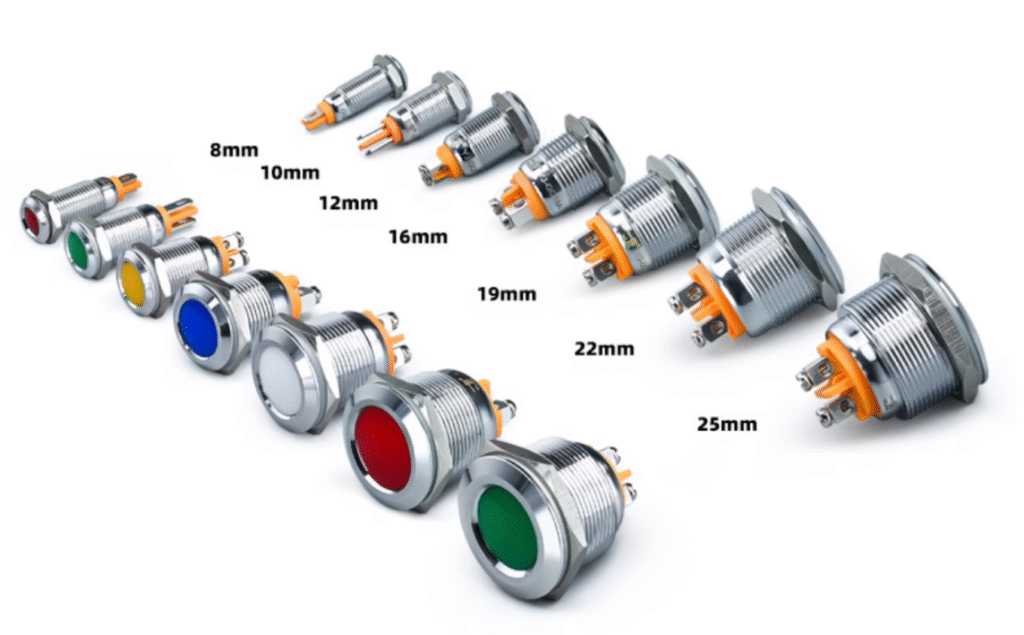

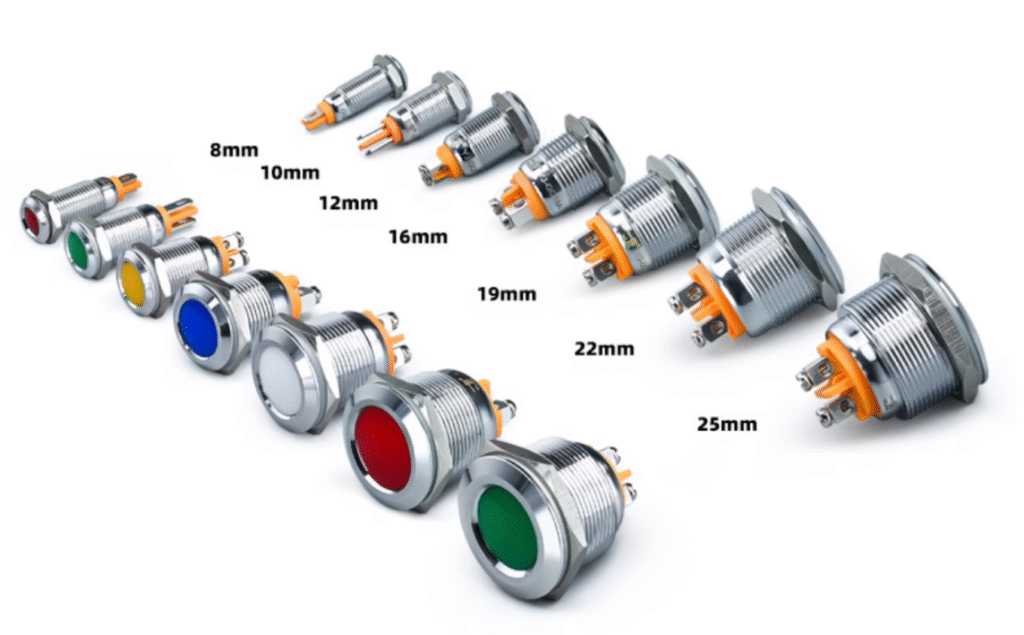

- Installation dimensions: Φ6/8/10/12/16/19/22/25 mm.

- Lamp voltage: 3、6、12、24、36、48、110、220V.

- Wiring mode: screw terminal、pin terminal、10mm wires.

- The material of the shell: chrome plating of brass、stainless steel、

aluminum alloy plating. - The material of the lampshade: PC.

- The material of the terminal: brass.

- The material of base: PA66.

- IP degree: IP67.

Metal signal lamp

Industrial Metal Signal lamp: Unveiling the Power of IP67, Diverse Sizes, Voltages, and Colors

In the dynamic realm of industrial operations, effective communication of status, warnings, and information is crucial for ensuring safety, optimizing efficiency, and maintaining seamless processes. Industrial metal signal lamp play a pivotal role in this regard, serving as highly visible and reliable visual cues that convey critical messages across various industrial environments. This article delves deep into the world of industrial metal signal lamp, exploring the significance of IP67 protection, the diverse range of sizes, voltages, and colors available, and how these features make them indispensable assets in industrial settings.

Understanding IP67 Protection: The Shield Against Harsh Environments

One of the most prominent features of industrial metal signal lamp is their IP67 rating. The Ingress Protection (IP) code is an international standard (IEC 60529) that classifies and provides a guideline to the degree of protection provided by mechanical casings and electrical enclosures against intrusion, dust, accidental contact, and water.

An IP67 rating means that the signal indicator offers complete protection against dust ingress (the “6” in the code) and can withstand immersion in water up to 1 meter for 30 minutes without harmful effects (the “7” in the code). This high level of protection makes IP67 – rated industrial metal signal lamp ideal for use in a wide variety of challenging industrial environments.

In factories where heavy machinery generates large amounts of dust, such as those in the mining, construction material production, or woodworking industries, the dust – tight feature of IP67 lamp ensures that the internal components remain free from dust accumulation. Dust can cause malfunctions in electrical components over time, but with IP67 protection, the lifespan and reliability of the signal lamp are significantly extended.

For applications near water sources or in areas prone to occasional flooding, such as food processing plants, wastewater treatment facilities, or marine – related industrial operations, the water – resistant property of IP67 signal lamp is invaluable. They can continue to function properly even when briefly submerged, preventing damage from moisture and ensuring uninterrupted operation.

Diverse Sizes: Tailoring to Specific Industrial Requirements

Industrial metal signal lamp are available in a wide range of sizes, including 6mm, 12mm, 16mm, 19mm, 22mm, and 25mm. Each size offers unique advantages and is suitable for different industrial applications, depending on factors such as visibility requirements, available installation space, and the nature of the message being conveyed.

6mm Signal lamp

The 6mm industrial metal signal lamp are the smallest in the range. Their compact size makes them perfect for applications where space is extremely limited, such as in control panels with a high density of components or in small – scale machinery. Despite their small size, they can still emit a bright and visible light, making them useful for indicating minor status changes or low – priority signals. For example, in a complex electronic control unit for a robotic arm, 6mm lamp can be used to show the normal operation of individual sub – systems.

12mm Signal lamp

12mm signal lamp strike a balance between size and visibility. They are commonly used in general – purpose industrial applications where a moderate – sized indicator is required. In factory automation systems, 12mm lamp can be installed on conveyor belts to signal the start, stop, or jam status of the belt. Their size allows for easy installation in various locations on the equipment, and the light output is sufficient to be noticed by operators in a busy industrial environment.

16mm Signal lamp

With a slightly larger diameter than the 12mm models, 16mm industrial metal signal lamp offer enhanced visibility. They are often employed in applications where a more prominent visual cue is needed, such as in the control rooms of power plants. In a power plant control room, 16mm lamp can be used to display the status of major electrical systems, such as generators or transformers. The larger size ensures that operators can quickly identify the status of these critical components from a distance.

19mm Signal lamp

19mm signal lamp are a popular choice for industrial applications that require a relatively large and highly visible indicator. In automotive manufacturing plants, 19mm lamp can be used on assembly lines to signal quality control issues. For instance, if a component fails a certain inspection, a 19mm red indicator can be activated to alert the workers on the line, ensuring that the defective product is not passed on to the next stage of production.

22mm Signal lamp

The 22mm industrial metal signal lamp are among the larger sizes available. They are suitable for applications where maximum visibility is crucial, such as in outdoor industrial facilities or large – scale manufacturing plants. In an open – air chemical processing plant, 22mm lamp can be used to signal safety hazards, such as the presence of a gas leak. Their large size and bright light output make them easily noticeable even in bright sunlight or adverse weather conditions.

25mm Signal lamp

25mm signal lamp are the largest in this range. They are typically used in applications where a highly prominent and attention – grabbing visual signal is required. For example, in airport ground support equipment, 25mm lamp can be used to signal the approach or departure of aircraft – related vehicles. The large size of these lamp ensures that they can be seen from a long distance, enhancing safety and coordination on the airport tarmac.

Multiple Voltages: Compatibility with Diverse Industrial Power Systems

Industrial metal signal lamp are designed to operate at various voltages, including 3V, 6V, 12V, 24V, 36V, 48V, 110V, and 220V. This wide range of voltage compatibility makes them suitable for integration into different industrial power systems, ensuring seamless operation regardless of the existing electrical infrastructure.

Low – Voltage Options (3V – 48V)

The low – voltage signal lamp, such as those operating at 3V, 6V, 12V, 24V, 36V, and 48V, are often used in applications where energy efficiency and safety are paramount. In battery – powered industrial equipment, such as mobile robots used for inventory management in warehouses, 12V or 24V signal lamp can be used. These low – voltage lamp consume less power, helping to extend the battery life of the equipment. Additionally, low – voltage systems are generally safer to work with, reducing the risk of electrical shock for maintenance personnel.

In control systems that use DC power, low – voltage signal lamp are also commonly employed. For example, in a programmable logic controller (PLC) – based automation system, 24V signal lamp can be easily integrated to display the status of different inputs and outputs. The use of low – voltage lamp in these systems simplifies the wiring and reduces the complexity of the electrical design.

Medium – and High – Voltage Options (110V and 220V)

The 110V and 220V industrial metal signal lamp are typically used in applications that are directly connected to the main electrical supply in industrial facilities. In large – scale manufacturing plants, where the electrical infrastructure operates at these standard voltages, 110V or 220V signal lamp can be used to signal the status of major electrical equipment, such as large motors or heating systems. These higher – voltage lamp can provide a more powerful and brighter light output, which is necessary for indicating critical status changes over long distances or in large industrial spaces.

In commercial buildings that house industrial – like operations, such as data centers or large – scale server farms, 220V signal lamp can be used to display the status of power distribution systems, ensuring that technicians can quickly identify any power – related issues.

A Spectrum of Colors: Conveying Messages with Clarity

Industrial metal signal lamp are available in a variety of colors, including red, green, blue, yellow, and white. Each color has a specific meaning and is used to convey different types of messages in industrial settings, following widely – recognized international standards and industry best practices.

Red lamp

Red is the color most commonly associated with danger, stop, or alarm. In industrial applications, red signal lamp are used to alert operators to potentially hazardous situations. For example, in a chemical plant, a red indicator might be used to signal a high – pressure situation in a storage tank or the presence of a toxic gas leak. Red lamp are also used to indicate the stop status of machinery. When a machine is shut down for maintenance or due to an emergency, the red indicator lights up, clearly communicating to all personnel in the area that the equipment is not in operation.

Green lamp

Green is the color of safety, normal operation, and go – ahead. Green signal lamp are used to show that a system or piece of equipment is operating normally and safely. In a manufacturing assembly line, a green indicator might be used to signal that the production process is running smoothly, and it is safe for workers to proceed with their tasks. Green lamp are also commonly used to indicate that a power supply is stable or that a safety interlock system is engaged and functioning properly.

Blue lamp

Blue signal lamp are often used to indicate a specific function or a call for attention in a non – hazardous way. In some industrial control systems, blue lamp can be used to signal that a particular program or operation is in progress. For example, in a computer – controlled machining center, a blue indicator might light up when the machine is in the process of executing a complex machining program. Blue can also be used to indicate a service – related message, such as when a machine requires routine maintenance but is still safe to operate in the short term.

Yellow lamp

Yellow is the color of caution and warning. Yellow signal lamp are used to alert operators to potential problems or abnormal conditions that may not be immediately dangerous but require attention. In a factory, a yellow indicator might be used to signal that a machine is operating at a sub – optimal level, such as when the temperature of a motor is slightly higher than normal. Yellow lamp are also used to warn of approaching hazards, such as in areas where forklift traffic is common, to alert pedestrians to be cautious.

White lamp

White signal lamp can be used for general status indication or to provide illumination in some cases. In industrial control panels, white lamp can be used to show the status of less – critical functions, such as the operation of a cooling fan in an electrical enclosure. White light can also be used in combination with other colors to enhance visibility or to provide additional information. For example, in some complex industrial systems, a white – lit indicator might be used to show the overall system status, while other colored lamp are used for more specific function – related messages.

Applications of Industrial Metal Signal lamp

The combination of IP67 protection, diverse sizes, multiple voltages, and a wide range of colors makes industrial metal signal lamp suitable for a vast array of applications across different industries.

Manufacturing Industry

In manufacturing plants, industrial metal signal lamp are used extensively. They are installed on production machinery to signal the start, stop, and fault status of the equipment. The different sizes of lamp allow for easy integration into various machine designs, and the IP67 rating ensures reliable operation in the often – dusty and dirty manufacturing environment. The color – coded lamp help operators quickly understand the status of the machinery, improving productivity and reducing the risk of accidents.

Energy Sector

In power plants, both thermal and renewable, industrial metal signal lamp play a crucial role. They are used to display the status of generators, transformers, and other electrical equipment. The high – voltage – compatible lamp are used to signal the operation and fault status of major electrical systems, while the color – coded lamp help technicians and operators quickly identify any issues. The IP67 – rated lamp are suitable for use in outdoor substations and other areas where they may be exposed to the elements.

Transportation and Logistics

In the transportation and logistics industry, industrial metal signal lamp are used in warehouses, ports, and airports. In warehouses, they are used on automated storage and retrieval systems to signal the status of the equipment and the availability of storage locations. At ports and airports, the large – sized lamp are used to signal the movement of vehicles, the status of loading and unloading operations, and safety – related messages. The IP67 protection ensures that the lamp can withstand the harsh environmental conditions, such as saltwater spray in ports or strong winds in airports.

Oil and Gas Industry

The oil and gas industry operates in some of the most challenging environments, both onshore and offshore. Industrial metal signal lamp with IP67 protection are essential for use in oil refineries, gas processing plants, and offshore platforms. They are used to signal the status of pipelines, valves, and other critical equipment. The different voltage options allow for easy integration into the complex electrical systems of these facilities, and the color – coded lamp help workers quickly identify potential hazards and operational statuses.

Conclusion

Industrial metal signal lamp with their IP67 protection, diverse range of sizes (6mm, 12mm, 16mm, 19mm, 22mm, 25mm), multiple voltage options (3V, 6V, 12V, 24V, 36V, 48V, 110V, 220V), and a variety of colors (red, green, blue, yellow, white) are indispensable components in modern industrial operations. They provide reliable and highly visible visual cues that are essential for ensuring safety, optimizing efficiency, and maintaining seamless processes across a wide range of industries.

FAQ

What is a push button switch?

A push button switch is an electrical component designed to be pressed or pushed by the user to make or break an electrical circuit. It is commonly used in various applications to control electric current.

What is the function of a tactile push button switch?

Tactile pushbutton switches are designed to provide tactile feedback when pressed. They usually have a small bump or dome under the button, allowing the user to feel a physical “click” or resistance when the switch is actuated.

How do I choose the correct pushbutton switch for my application?

To select the appropriate pushbutton switch, consider the required voltage and current ratings, circuit type (AC or DC), environmental conditions (e.g., humidity, temperature), installation requirements, and desired function (momentary, latching, illuminated, etc.).

Are pushbutton switches suitable for industrial use?

Yes, push button switches are widely used in industrial applications. They are known for their durability, reliability, and ability to handle high currents or voltages. Industrial-grade switches typically have rugged construction and meet specific industry standards for performance and security.

How to install push button switch?

The installation process may vary depending on the specific switch and application. Generally speaking, push button switches can be panel mounted or PCB mounted. Panel mount switches require a hole in the control panel or housing, while PCB mount switches are soldered directly to the printed circuit board.

Are pushbutton switches suitable for outdoor use?

Certain pushbutton switches are designed to withstand outdoor environments, including exposure to moisture, dust, and temperature changes. Look for a switch with the appropriate IP rating, or consult the manufacturer for a switch specifically designed for outdoor applications.

Can the product and packaging be customized?

Yes. We have customized a lot for customers before. Includes different button shapes, colors and terminals. Custom switches can be tailored to specific brand or application requirements.

Regarding the customization of packaging, we can put your logo or other information on the packaging, no problem. It’s just that this will incur some additional costs.

Can you provide samples? Is the sample free?

Yes, we can provide samples. But you need to pay for the freight. If the sample needs more quantity, we will charge the sample fee.

Can I become an agent/reseller?

welcome! But please let me know first and check your country. If you want any other kind of cooperation, please feel free to contact us.