Application of Yijia limit switch in automated production line

In the field of industrial production, the degree of automation is getting higher and higher, and industrial robots, as an important production tool, have been widely used in various industries.

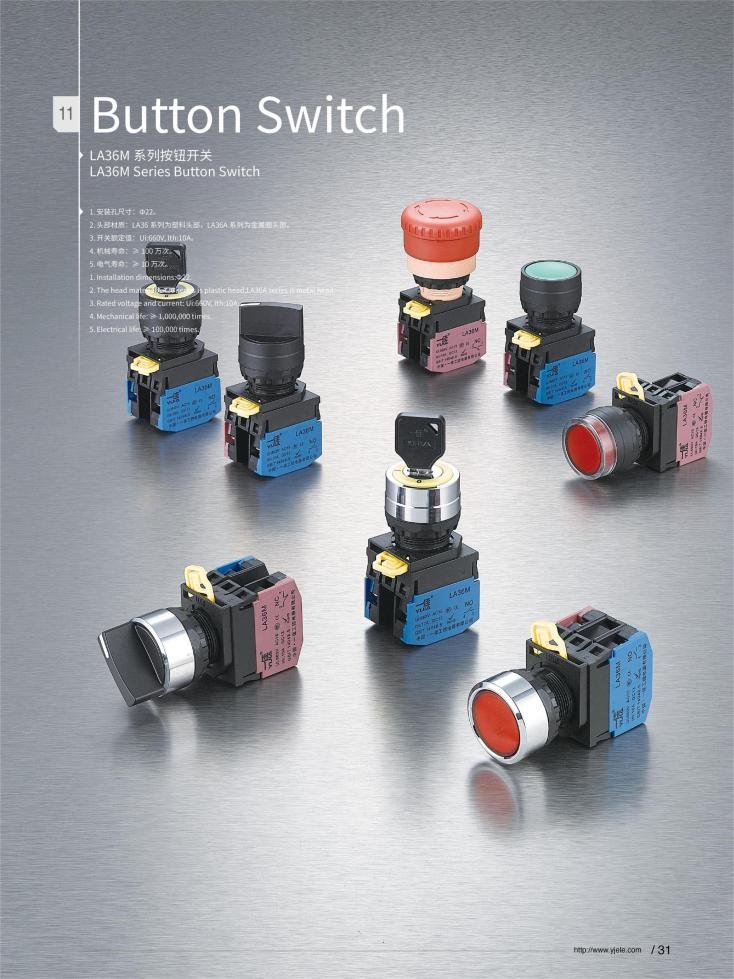

In order to meet the demanding control requirements of industrial robots, Yijia has introduced the Limit switch series of push-button switches designed specifically for industrial environments.

With its rugged design, high level of protection, various specifications and modes of operation, and easy installation, the switches are a reliable partner in the field of industrial robot control.

Yijia limit switches are key in automated production lines, playing an important role in positioning, control, handling, and emergency stop. Through precise position detection and control, limit switches ensure that the machine stops or moves to a specific position accurately during work, achieving efficient operation of the production line. In addition, it is also used to monitor the status of safety doors and protective devices to improve the safety of industrial environments. The versatility of limit switches makes them an indispensable key component in industrial automation, promoting accurate and safe management of production processes.

Application of limit switch in mechanical positioning

Limit switch are widely used to achieve precise position control. These switches detect the position of the machine to ensure that it can accurately stop or move to the predetermined position during the working process. Through the connection with the control system, the limit switch can trigger the stop or start operation of the machine, thereby effectively controlling the movement of the machine.

The working principle of the limit switch includes precise position detection and stop and start control. Through mechanical or non-mechanical means, the limit switch can detect the movement, rotation or linear movement of the machine. Once the machine reaches the predetermined position, the limit switch sends a signal to the control system to trigger the corresponding action. This helps to avoid process errors and ensure that the machine stops at the right time, thereby improving the efficiency of the production line.

The application of limit switch is particularly important in automated assembly lines or processing lines. The machine needs to be in a specific position to perform assembly or processing tasks, and the limit switch ensures that these tasks proceed as planned. This not only helps to improve production efficiency, but also prevents the machine from running in the wrong position or performing wrong operations.

In addition to improving efficiency, limit switch also play a key safety role in mechanical positioning. Machine movement can involve safety issues, and limit switches can ensure that the machine stops in a safe position, helping to prevent accidents and ensuring the safety of workers and equipment.

Application of limit switch in conveyor belt control

First, limit switch are used to accurately detect the position of objects on the conveyor belt. By accurately installing limit switches, the system can determine whether the object has reached the preset position, providing key position information for subsequent control.

Second, limit switch can trigger the stop or start operation of the conveyor belt. Once the object reaches a specific position, the limit switch will work and send a signal to the control system to perform the corresponding action, such as stopping the conveyor belt, starting the next process, etc. This ensures that the material can be accurately positioned and controlled when needed, improving the efficiency of the production line.

In addition, the setting of limit switch also helps prevent conveyor belt overload or material accumulation. By setting limit switches at key positions, the system can automatically stop the conveyor belt when excessive material or accumulation is detected, avoiding potential problems and damage.

By connecting to the control system, the limit switch not only provides position information, but also directly affects the operation of the conveyor belt, improving the accuracy and efficiency of conveyor belt control. In some applications, limit switch can also be used to detect conveyor belt failures or abnormal conditions, trigger alarms or perform maintenance procedures in a timely manner.

Application in safety door control

In industrial production, safety doors are an important barrier to protect the safety of workers and equipment. Limit switches play a key role in safety door control, ensuring that the door is in the correct position when closed to prevent accidental opening.

The setting of limit switches also helps prevent the door from pinching people or objects when closing. By setting the position of the limit switch reasonably, when it is detected that the door is about to pinch an object, an emergency stop can be triggered to effectively avoid potential risks of injury.

In addition, limit switches are combined with automatic control systems to realize the automation of door control. By connecting to the control system, the limit switch directly affects the movement of the door, improving the accuracy and efficiency of door control. In some applications, limit switches can also be used to detect door failures or abnormal conditions, trigger alarms or perform maintenance procedures in a timely manner.

Application in tooling positioning

Limit switch play a key role in tooling positioning. One of its main functions is to ensure that the tooling or fixture is accurately positioned and fixed in the required position during the work process by detecting the position of the tooling or fixture. By accurately installing the limit switch, the system can monitor the position of the tooling in real time to ensure that it is in the expected working position.

Once the tooling or fixture reaches a specific position, the limit switch will come into play, triggering the control system to perform corresponding actions, such as fixing the tooling, starting the process, and performing other automated tasks. This ensures that the tooling can be accurately positioned and controlled when needed, improving the accuracy and efficiency of industrial production.

In addition, the setting of limit switches can prevent the tooling or fixture from performing operations in the wrong position, helping to avoid errors on the production line and improve production quality. At the same time, the application of limit switches also helps to realize the automation of the production process, integrate the precise control of tooling positioning into the automation system, and make the entire production process more efficient and controllable. In some applications, limit switches can also be used to realize the replacement and switching of tooling. Once it is detected that the current tooling has reached the predetermined position, the system can automatically perform tooling replacement and improve the flexibility of the production line.

Finally, limit switch also play a safety role in tooling positioning. They prevent tools from being operated in the wrong position, reducing the risk of danger and damage. Once a tool or fixture is detected to be out of position, the limit switch can trigger an emergency stop or other safety measures to ensure a safe working environment.